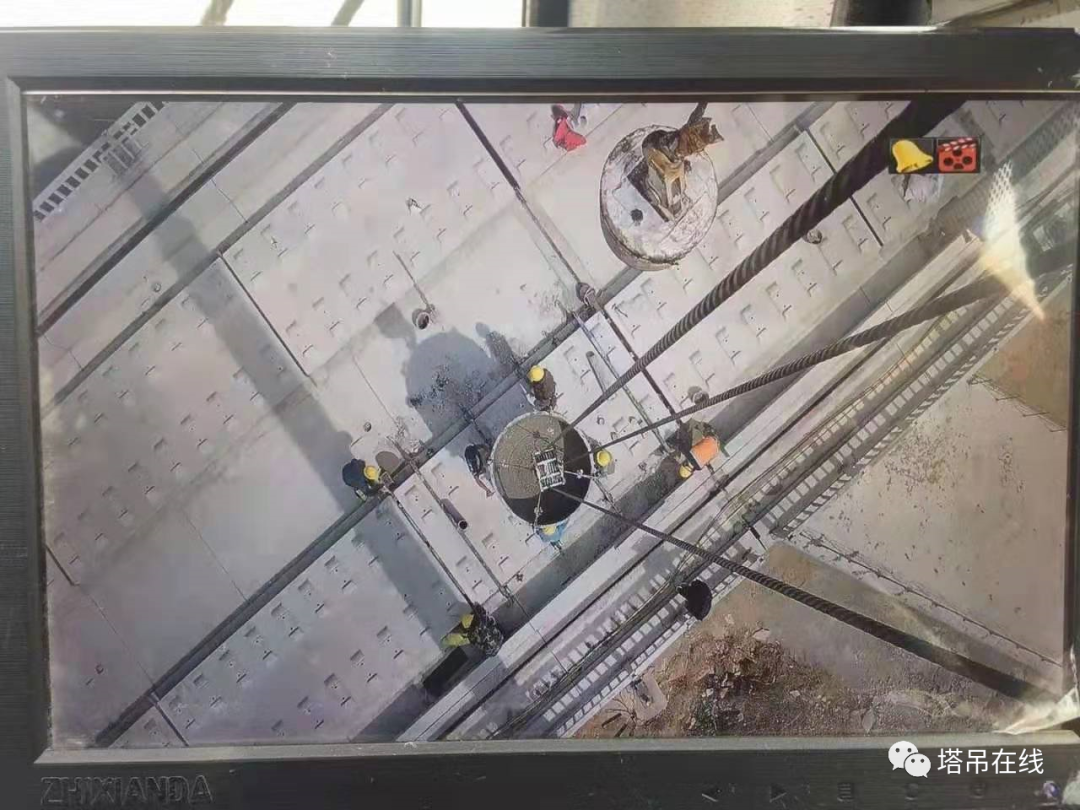

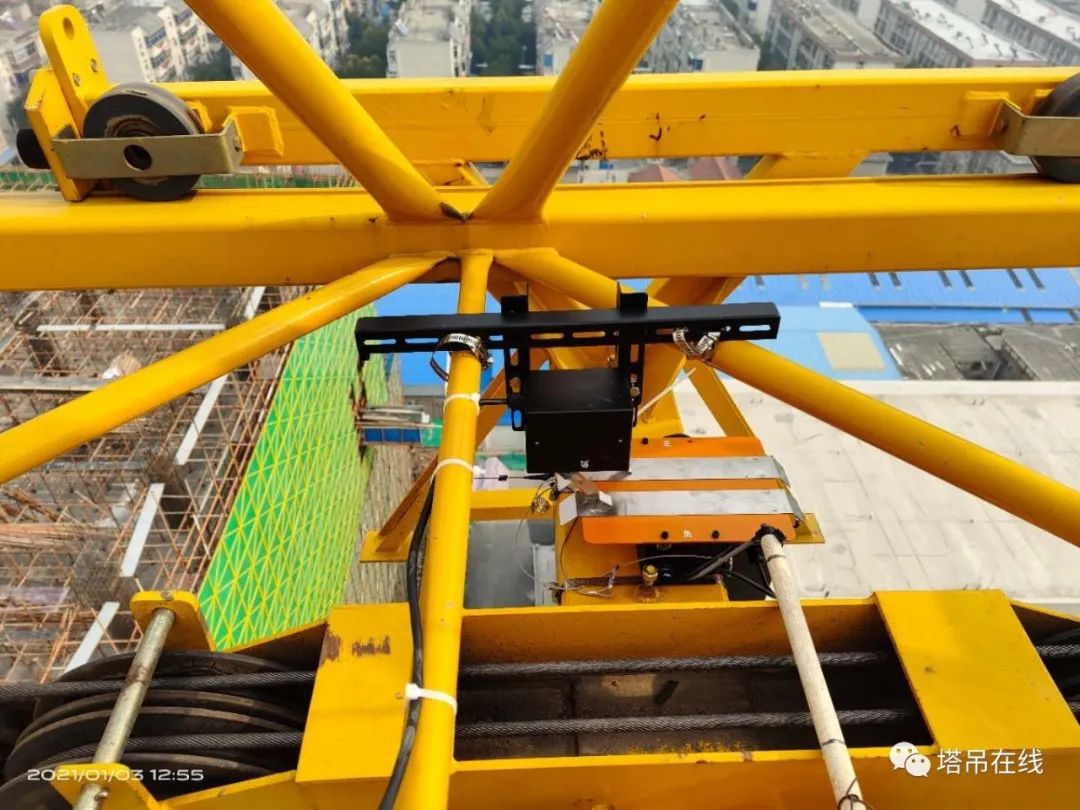

1: The hook visual camera and battery, and wireless sliding contact charging bracket are installed on the tower crane trolley.

Trolley version tower crane hook visualization system: the guidance system can display real-time video images around the hook to the tower crane driver in high definition images in real time, so that the driver can make correct operations and judgments quickly and accurately, and solve the industry problems of the tower crane driver’s visual dead angle at the construction site, remote visual blur, voice guidance prone to errors and so on.

The visual camera will automatically focus and track the real-time operation picture of the hook according to the distance of the lifting height rise and fall, and realize wireless transmission of video to the tower crane driver’s operation screen.

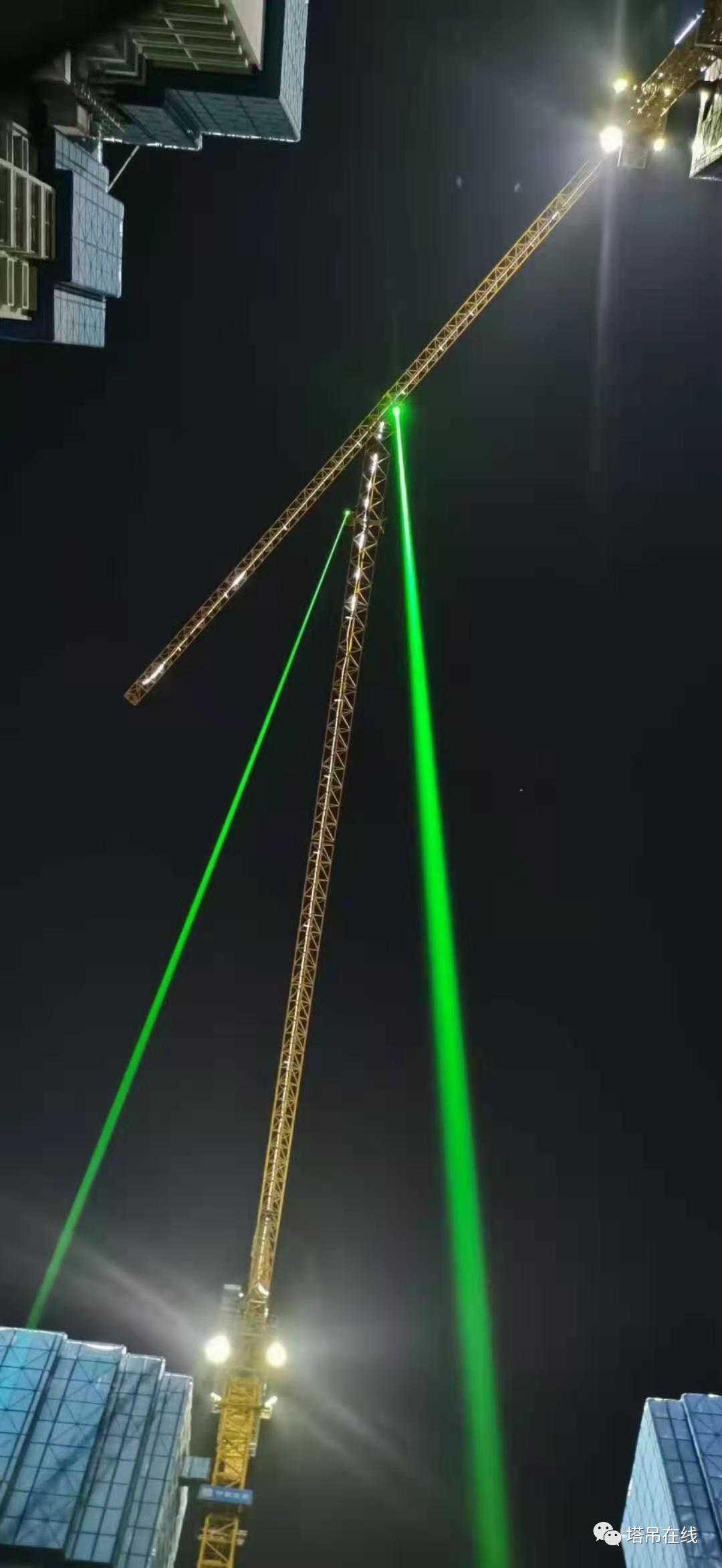

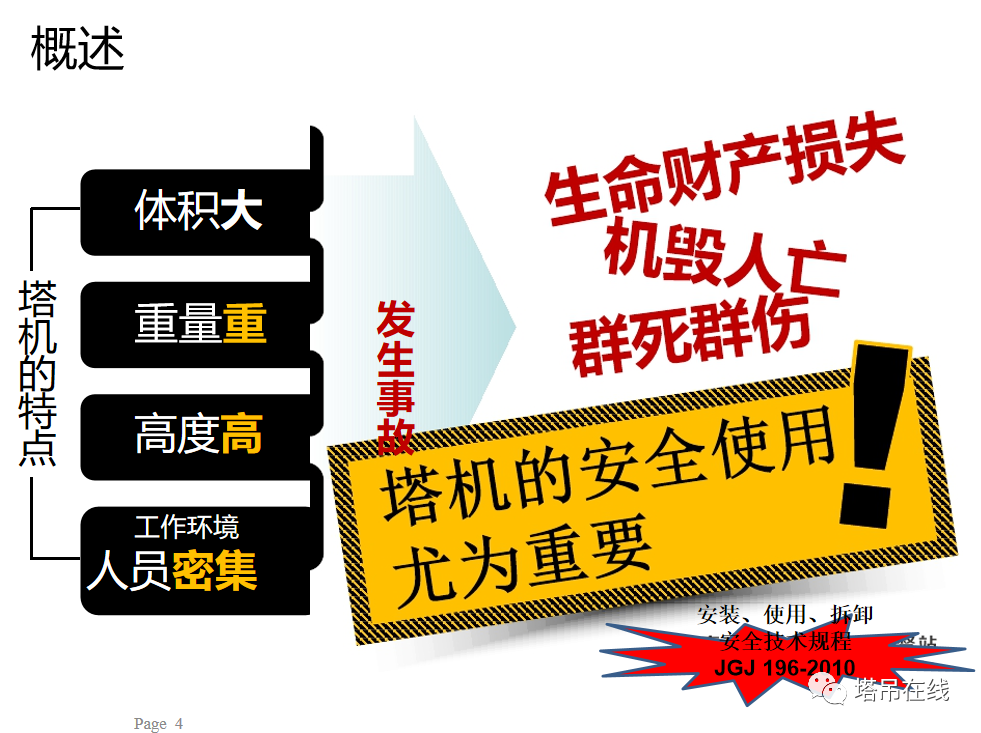

The key is to prevent tower crane safety monitoring system+tower crane hook visualization system to make tower crane construction safer.

It can effectively avoid the occurrence of accidents, and is an indispensable industry tool to improve the efficiency of on-site construction, reduce the rate of safety accidents, reduce labor costs, and promote digital standard construction sites under the new situation.

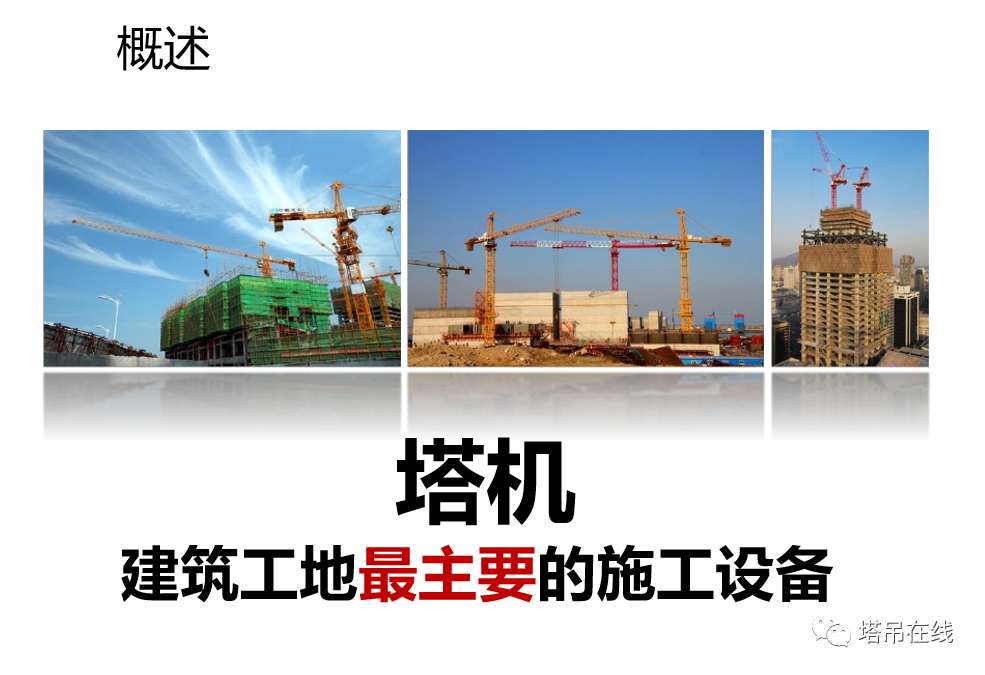

The key to safety is to manage accidents.

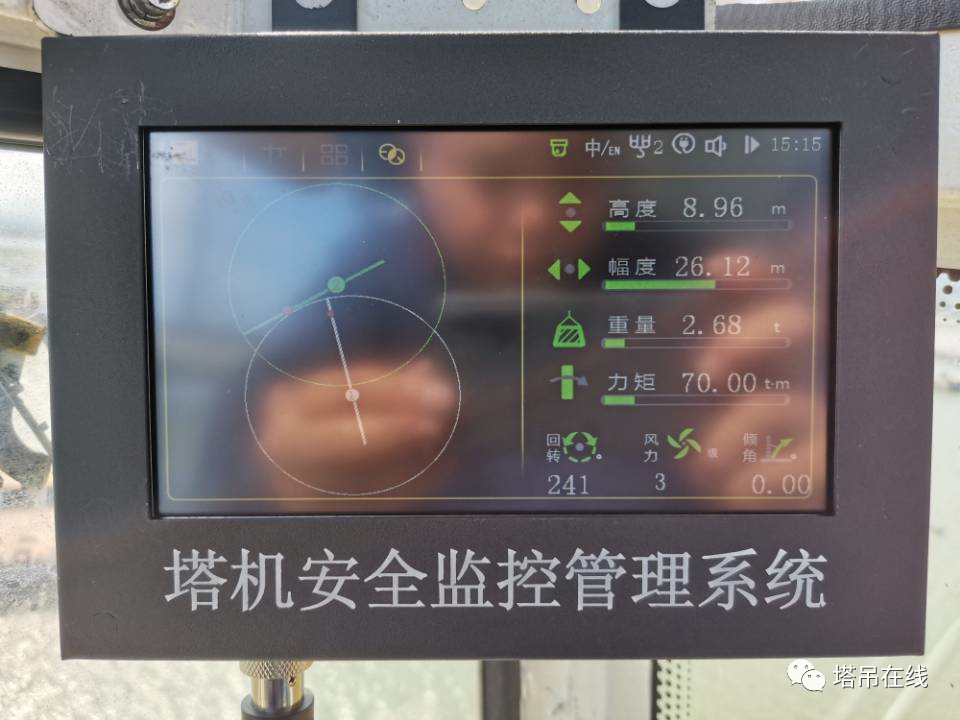

Monitor the operation safety indicators of the tower crane, including lifting load, lifting torque, luffing, height, working return angle and working height wind speed, area limit, anti-collision protection, audible and visual warning and alarm when approaching the rated limit, to realize automatic cut-off of dangerous operation of the tower crane: when dangerous situations such as over-limit and overload occur, the tower crane monitoring system can automatically realize the cut-off of dangerous behaviors, so that the tower crane can develop towards safe operation, Stop the tower crane from running in dangerous operation direction.

The tower crane safety monitoring anti-collision system monitors the tower crane operation status in real time.

The tower crane driver will monitor the lifting range without dead angle to reduce accidents caused by blind lifting..

.