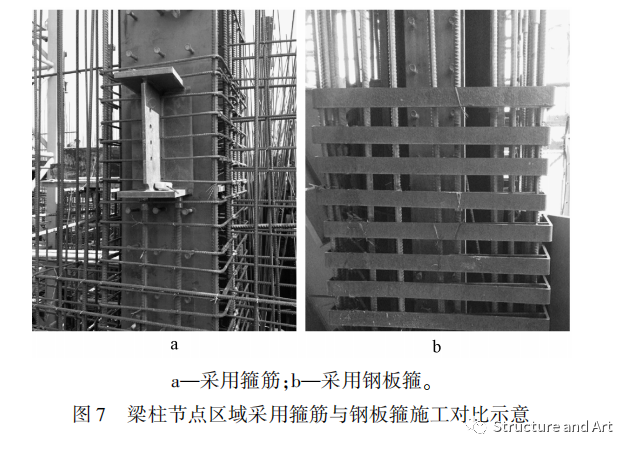

2、 In steel-concrete hybrid structures, the design of the beam column node area with steel plate hoops is a major challenge.

Because the push rules of WeChat official account have been adjusted, if you want to continue to receive the content of this official account, please set the “building structure” official account as the star sign, and click “watching” and “like” at the end of the text.

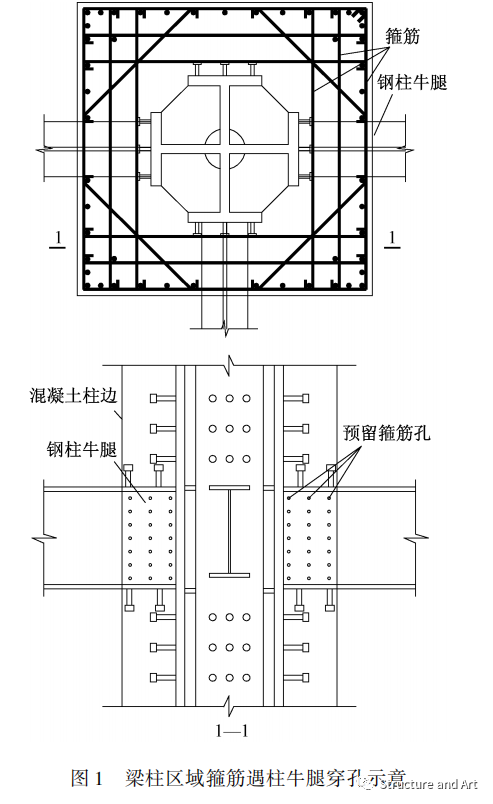

Due to construction and manufacturing errors, it is difficult for the stirrups to pass through the reserved holes, which brings great difficulties to construction.

When the steel plate hoop is welded to the column bracket in the steel component manufacturing factory for on-site construction, the longitudinal bars of the column are tied together with the steel plate hoop, which not only accelerates the construction progress but also ensures the construction quality.

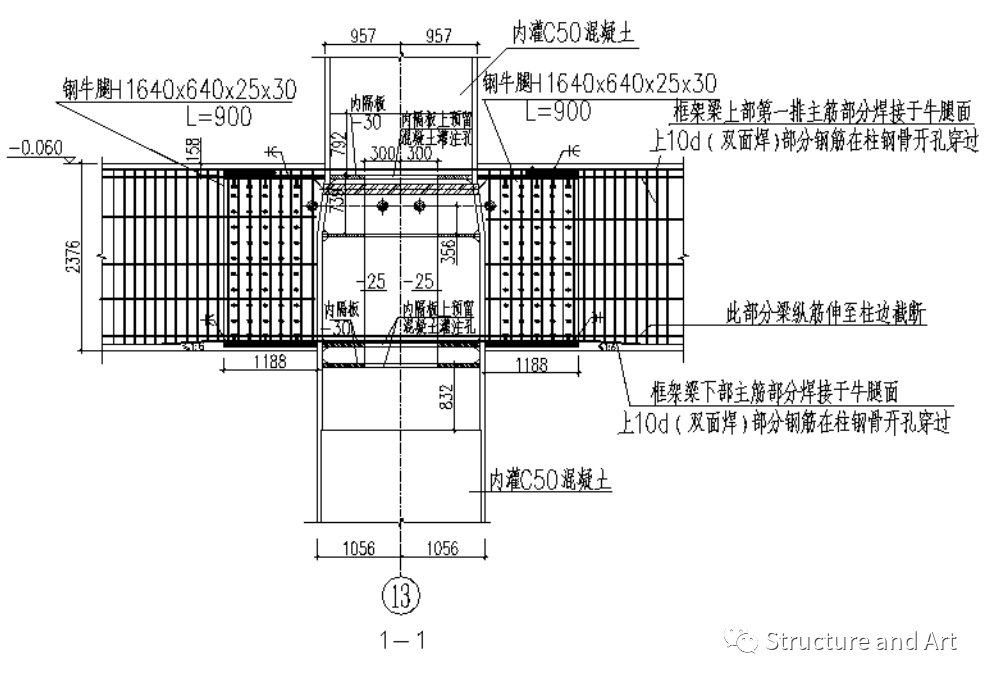

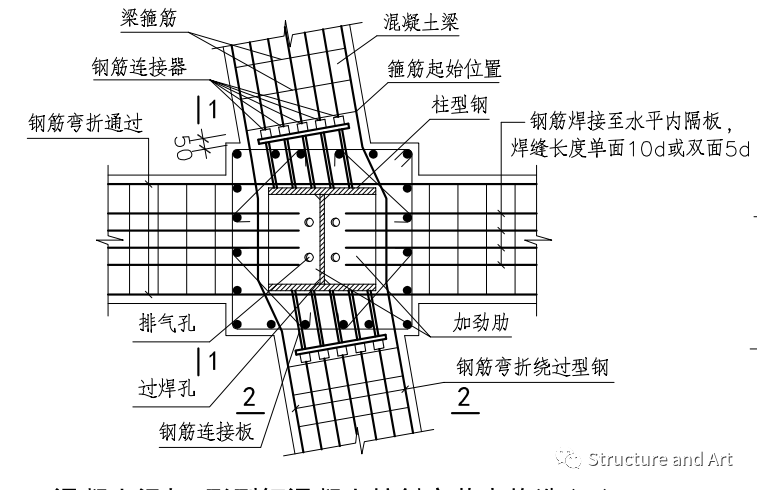

Due to the cross section of the steel and steel bars, the column hoops often need to be perforated on the steel column corbel when encountering it (Figure 1).

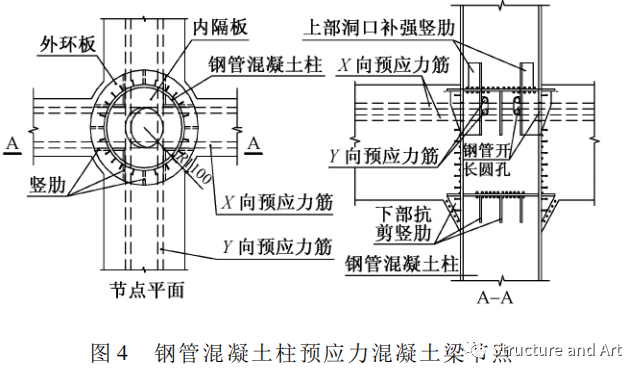

(3) Due to the presence of a large amount of steel bars in the beam column node area, the pouring of concrete is very difficult, making it difficult to vibrate and unable to ensure the density of the node area and lower concrete.

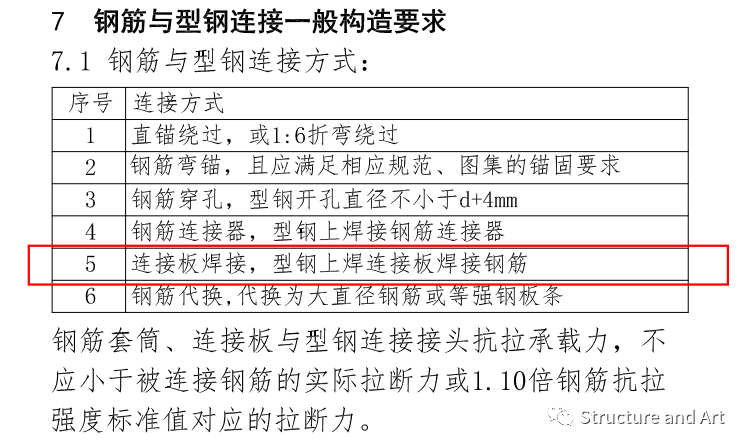

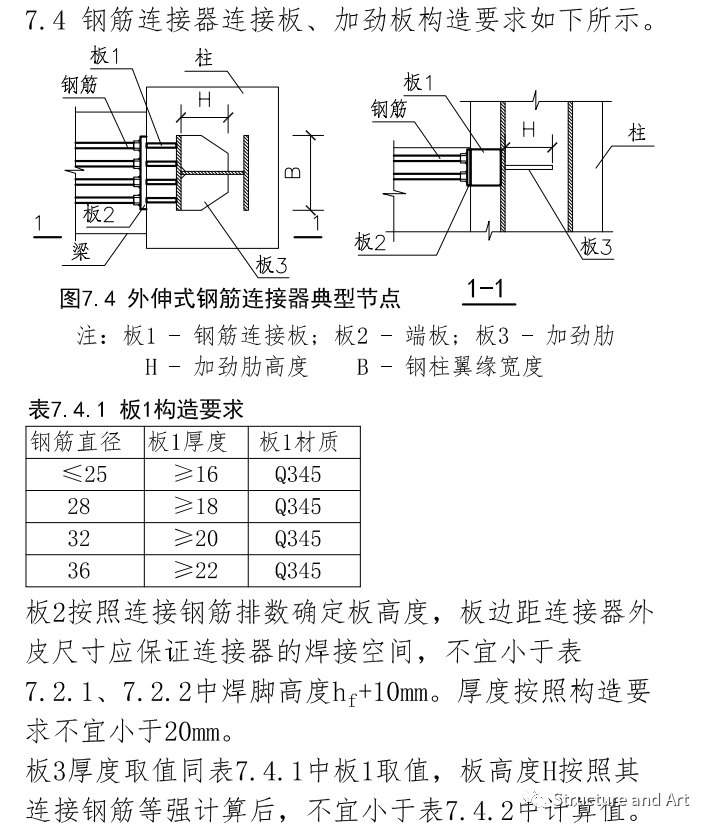

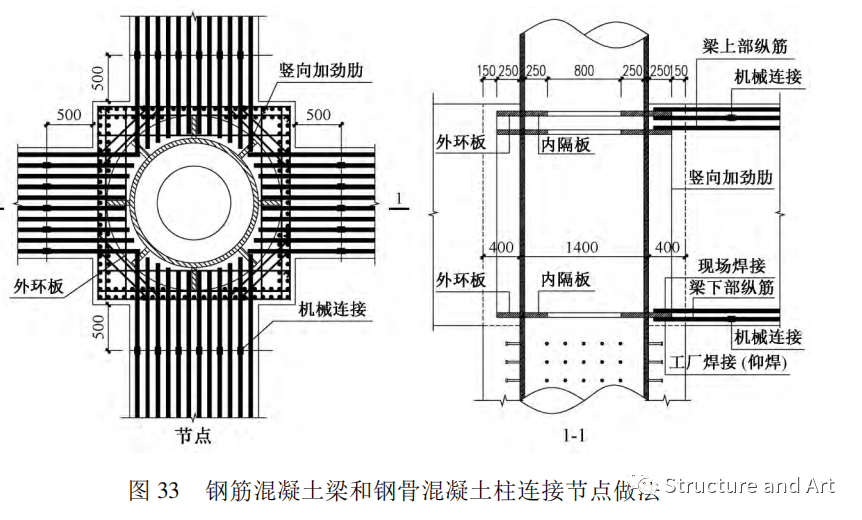

Among them, the steel plate strip connection is introduced as follows: 2.

The main drawbacks of using traditional stirrups in the node area are: (1) In order to ensure the strength of the section steel, the holes on the section steel should be as small as possible.

1.

Compared with the traditional situation that the reinforcement is welded to the horizontal short corbel, it is more convenient for construction.

Star logo setting: enter the home page of the official account, click “…” in the upper right corner, click “Set as star logo”, and a yellow pentagram will appear next to the public account name (the same operation for Android and iOS users) 1.

The proposal of steel plate hoops draws inspiration from the application of steel plate hoops in structural seismic resistance, and introduces steel plate hoops to replace the hoops in the beam column node area during design.

Typical node practice 3.

The steel plate connector can avoid the situation that the column reinforcement passes through the flange when the short corbel connection is used, and the steel plate strip is vertically downward, and there is a gap between the Flat noodles, which is convenient for concrete pouring.

Steel plate strip 1, 16G523-2 complex steel reinforced concrete structure node structure atlas gives several connection methods of longitudinal reinforcement and section steel.

2.

(2) When there are many stirrups in the column, more than 3 rows of holes may be reserved on one side of the bracket, which greatly weakens the cross-section of the bracket steel.

3.

Production process 1): Firstly, according to the size of the steel plate hoop in the deepening drawing, use corresponding materials and thicknesses of steel for layout, cutting and cutting into rectangular parts, and then use relevant mechanical equipment for bending to shape the parts and wait for the next welding step (Figure 4).

2) The steel plate hoop formed by welding, polishing, and processing is welded to the designated position of the steel column using CO2 gas shielded welding according to the detailed drawings

.

Method: Use steel plate clamps within the height of the highest steel beam connected to the steel column.