The cement blanket before setting can be cut or cut at will with ordinary hand tools.

During construction, it is not mixed on site.

After hydration, the cloth hardens rapidly to form a 5000 psi strength with rigidity, strong durability and waterproof.

3) Environment friendly cement blanket is a low-quality and low-carbon technology.

After hardening, the fiber improves the strength of the composite blanket and prevents cracking.

(David Asher, northern exposure (American television), famous cement quote) the floor is covered with waterproof lining.

As long as it is watered, it can form the necessary shape and hardness.

Due to the limited alkali content and low erosion rate, it has little impact on the local ecosystem.

5) With high material strength, the fiber in the cement blanket can improve the strength of the material, prevent cracks, absorb impact energy and form a stable failure mode.

Product features 1) easy to use, cement blanket can be provided in large quantities as a large reel.

You can also cut the size as needed.

The size and shape of the cement blanket can be processed within 2 hours, and the strength of 80 can be hardened within 24 hours.

The construction of cement blankets such as pond slope protection, river slope protection and ditch reconstruction is convenient, which can not only effectively prevent water and soil loss, but also strengthen and add force.

In addition, according to the special requirements of users, special formulas can be used to achieve the purpose of rapid solidification or delayed solidification.

Concrete GCCM is ideal for rapid cutting and fixing in place to strengthen or repair culverts or watersheds, foundations, dikes or other structures.

Cement blankets are widely used.

4) Application flexibility cement blanket has strong drapability, and can even form hyperboloid shape according to the complex shape of the covering surface.

More cloth can maintain flexibility for 2 hours and can be easily operated to adapt to the contour of irregular equipment.

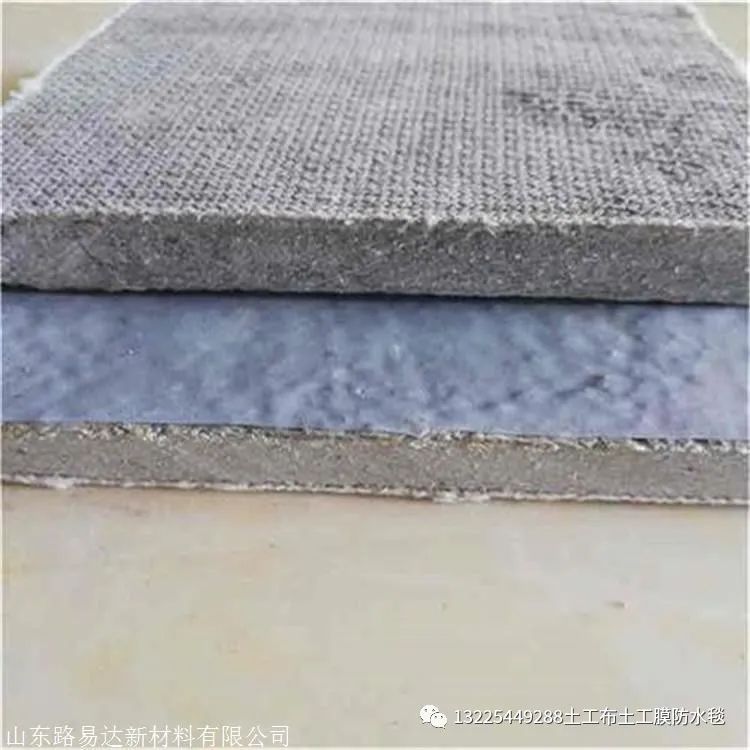

7) Waterproof characteristics: the bottom of the cement blanket is lined with polyethylene (PVC), which is completely waterproof and improves the chemical resistance of the material.

This unique material not only has the toughness of textiles, but also has the life and strength of concrete.

It has good toughness and can be hung vertically or placed in the groove.

It is laid according to the terrain and technical requirements, evenly sprayed with water, or soaked in water.

Cement blanket, also known as concrete canvas, is a new composite engineering material combined with cement and textile fiber technology, which is made of fiber bone penetration and multifunctional concrete powder.

It can be widely used in railway, highway, water conservancy, agricultural irrigation and other fields, flood control emergency embankment, dam seepage prevention, collapse management, landslide management and waterproof engineering…

The amount of materials used for many purposes is 95% less than that of ordinary concrete.

Cement blanket concrete geosynthetic cement composite pad (GCCM) is an innovative material technology, which can use concrete in slope, water and other inaccessible positions without form or mixing, and the requirements for equipment.

In addition, it is also provided by reel to facilitate manual loading, unloading and transportation without large crane.

6) Durable cement blanket has good chemical resistance, wind and rain erosion, and ultraviolet decomposition will not occur in the sun.

The concrete shall be prepared in a scientific proportion without on-site preparation, and there will be no excessive hydration problems.

Cement blankets can be solidified under water or sea water.

2) Rapid solidification molding occurs hydration reaction after watering.

8) Fire protection characteristics: the cement blanket does not support combustion, has good flame retardancy, and has small smoke when on fire, so the emission of dangerous gases is very small.

And only 15 kilograms per square meter, transportation is very convenient.

Concrete distribution GCCM is a roll engineering concrete with three-dimensional structure to strengthen concrete and provide strength and durability.