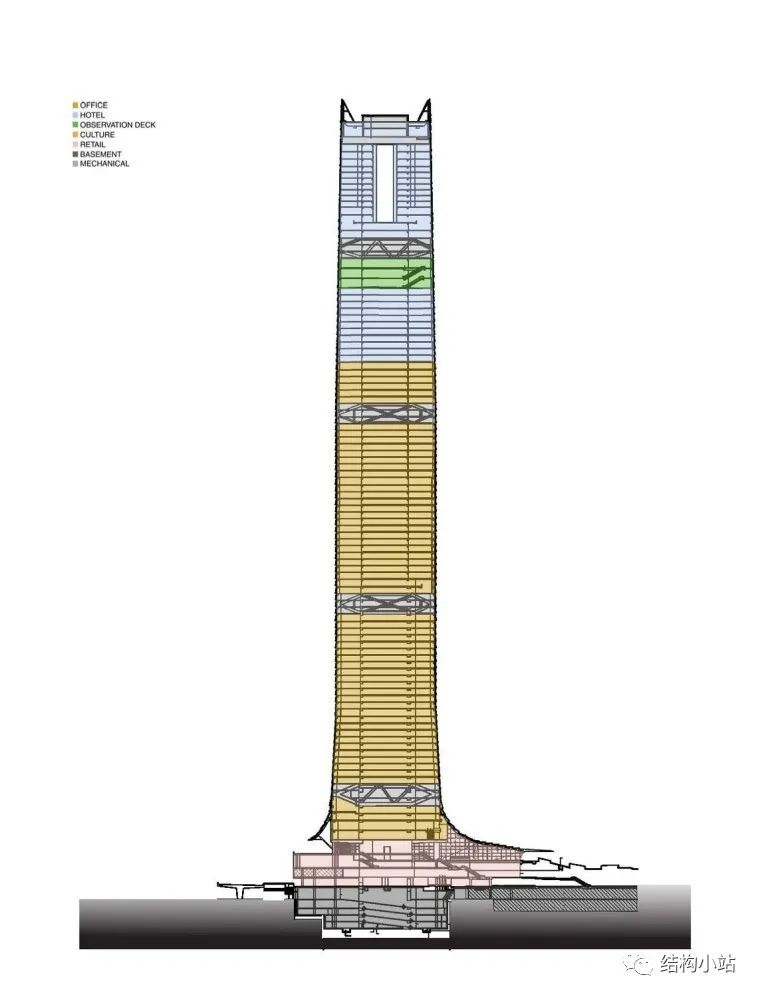

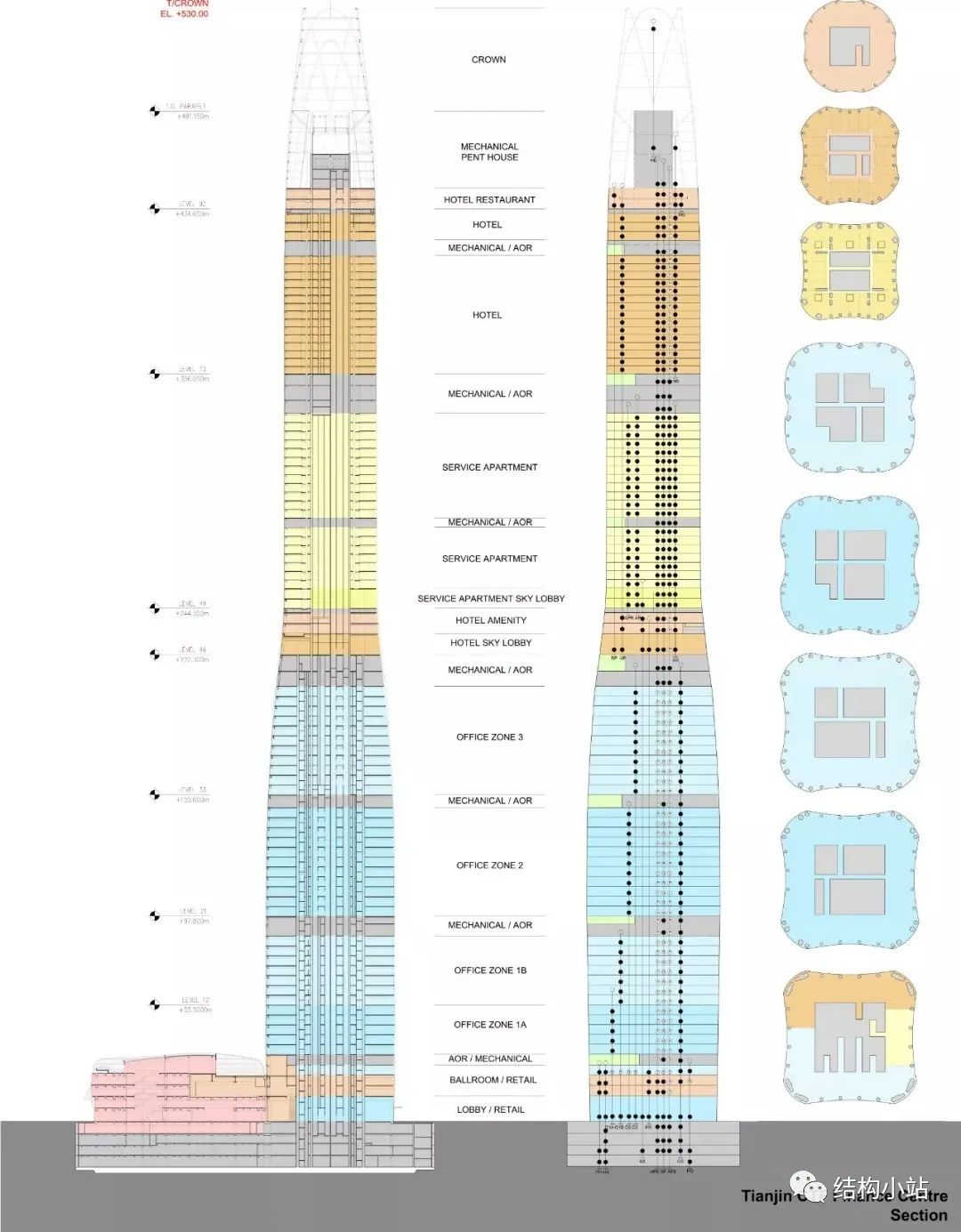

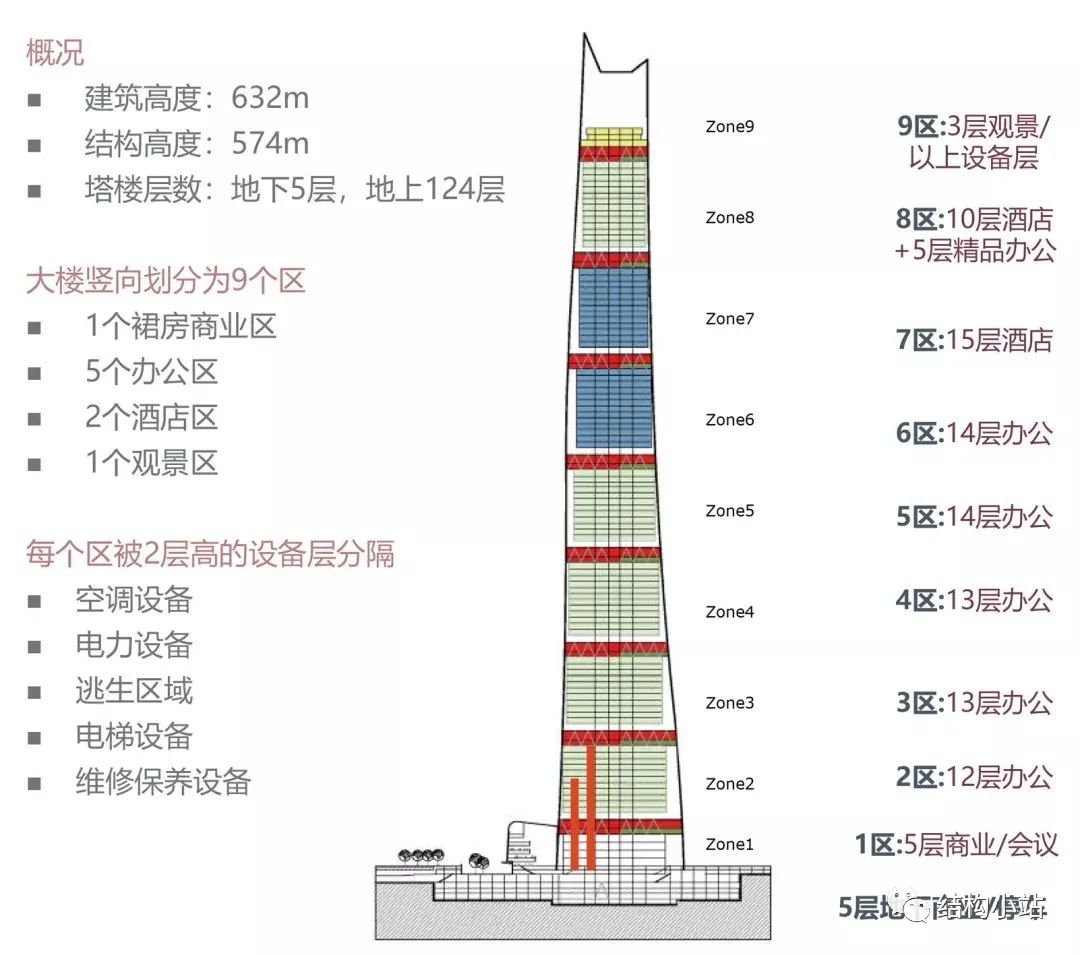

1 Shanghai central architectural design: Gensler&TJAD structure design: TT&TJAD structure system: mega frame core tube outrigger truss Shanghai Center Tower building height 632m, structural height 574m, main tower 124 floors, podium 5 floors, 5 underground floor, the construction area is about 578 thousand square meters.

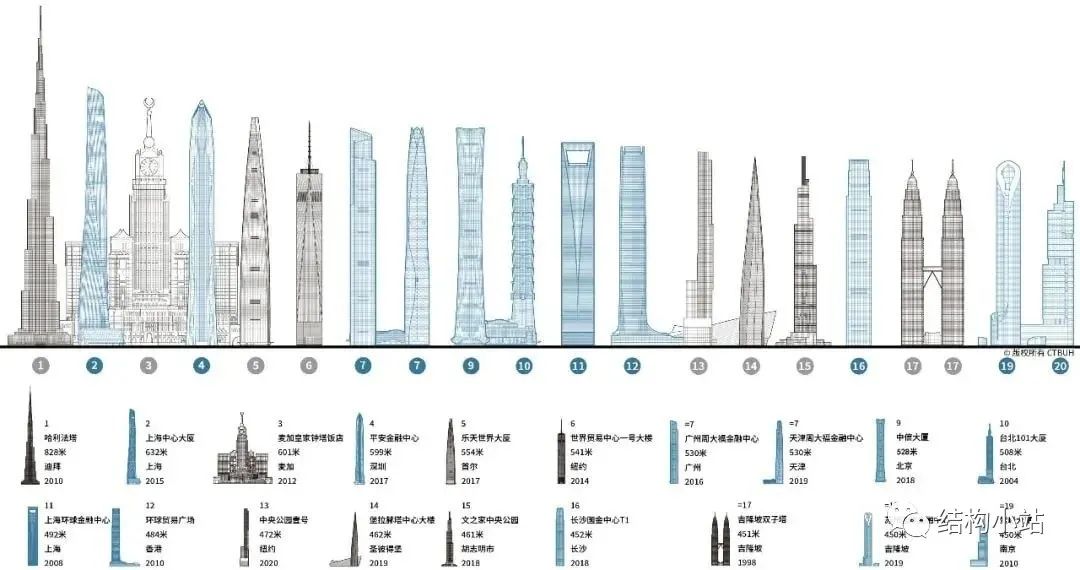

▲ by 2021, the world’s top 20 super high-rise buildings (@ CTBUH) have been built.

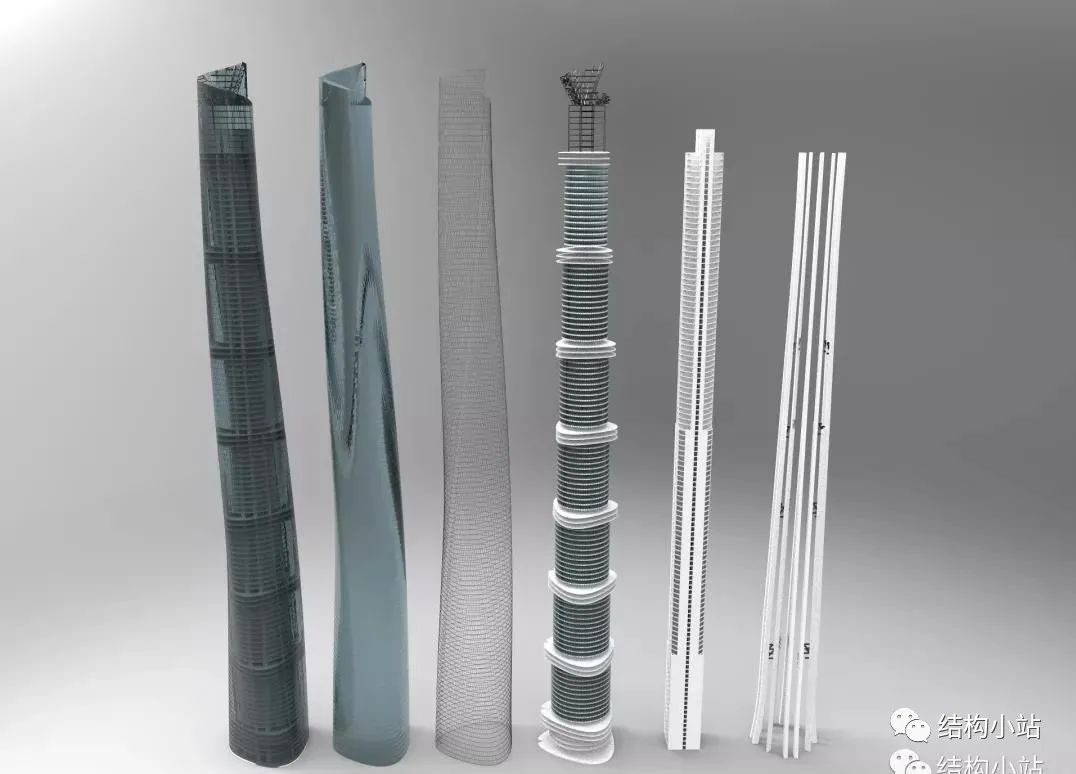

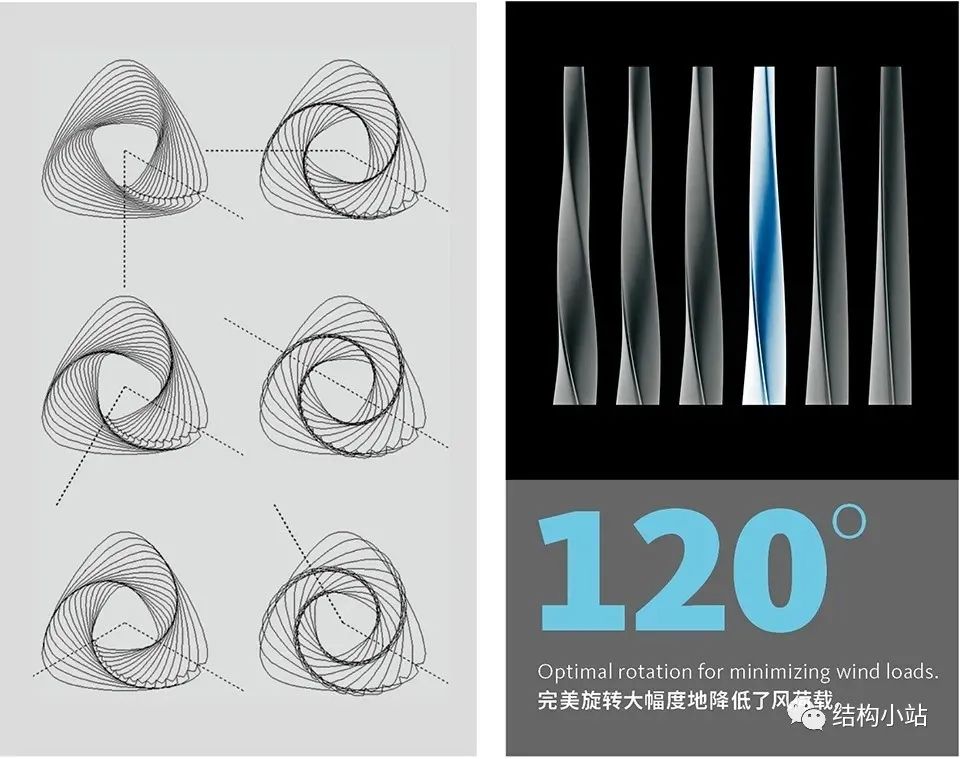

This smooth and smooth nonlinear torsional structure can effectively reduce the wind load of the structure.

Construction began in 2009 and lasted for 8 years.

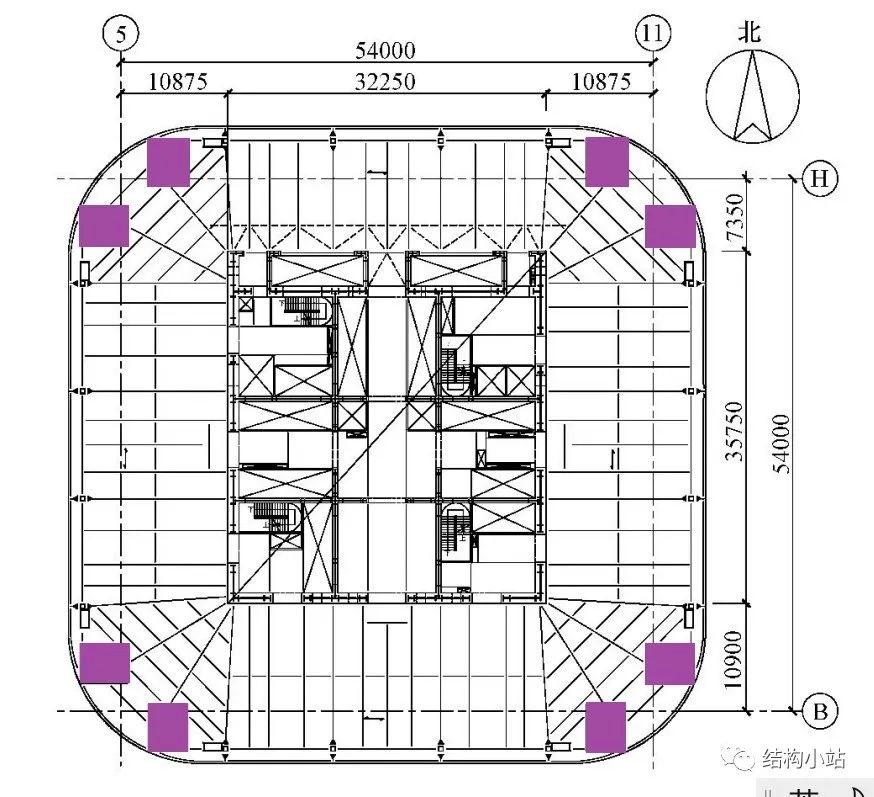

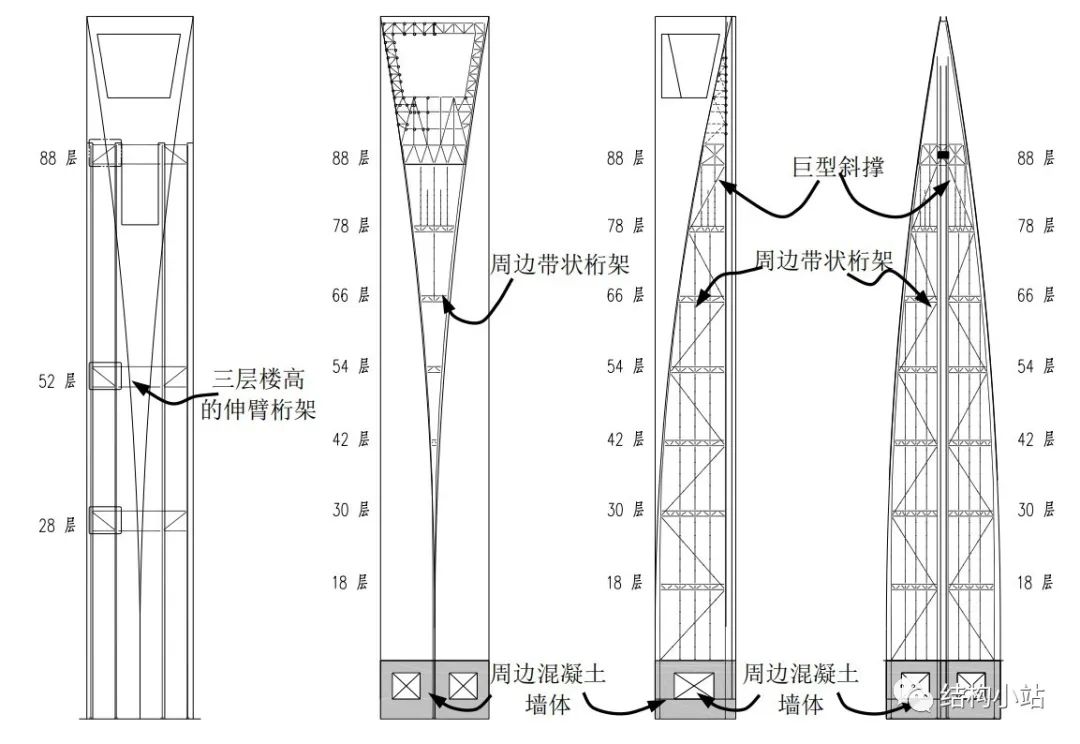

The four corner columns are mainly used to reduce the span of the ring truss and slow down the shear lag effect of the outer frame.

Through wind tunnel test, the shape reduces the wind load of about 24%.

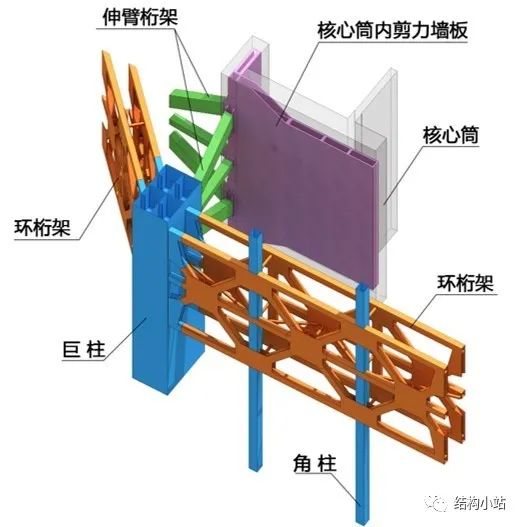

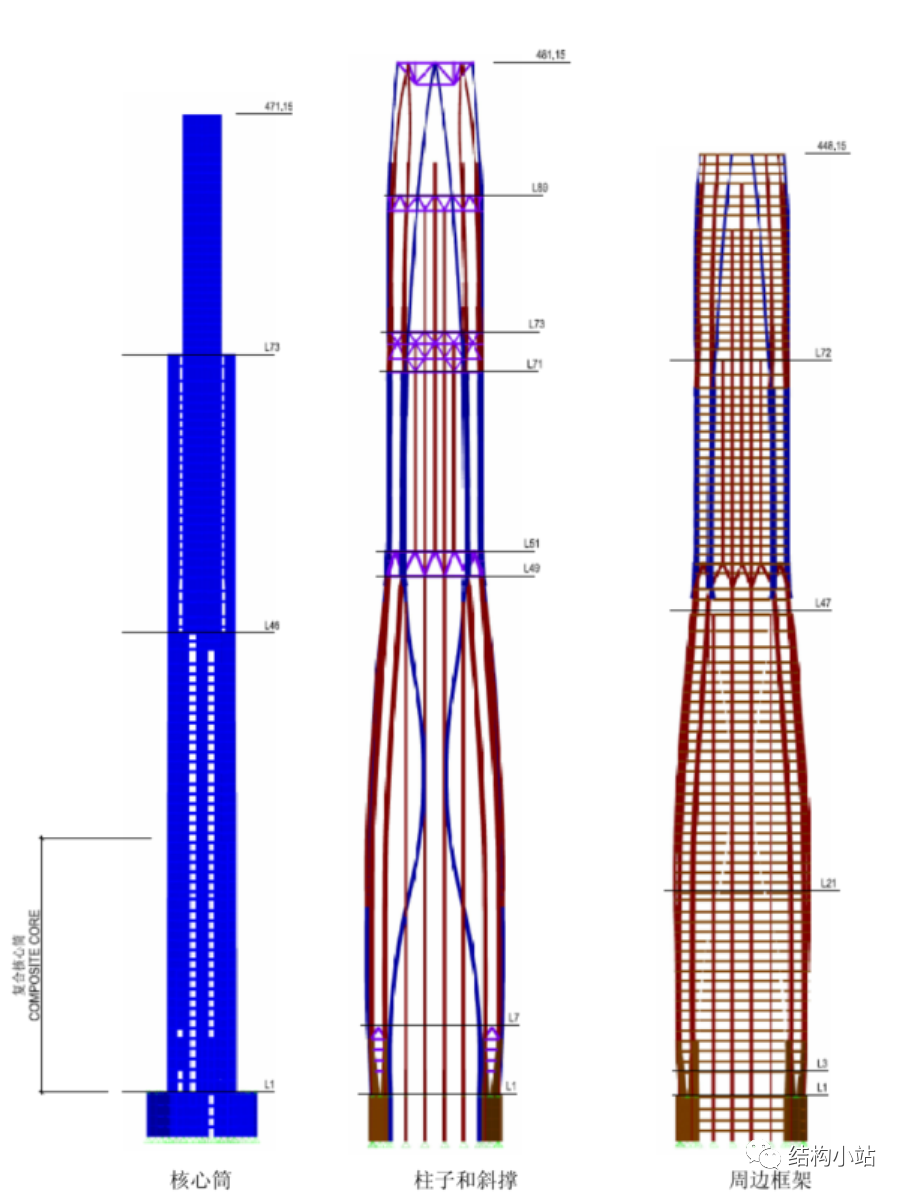

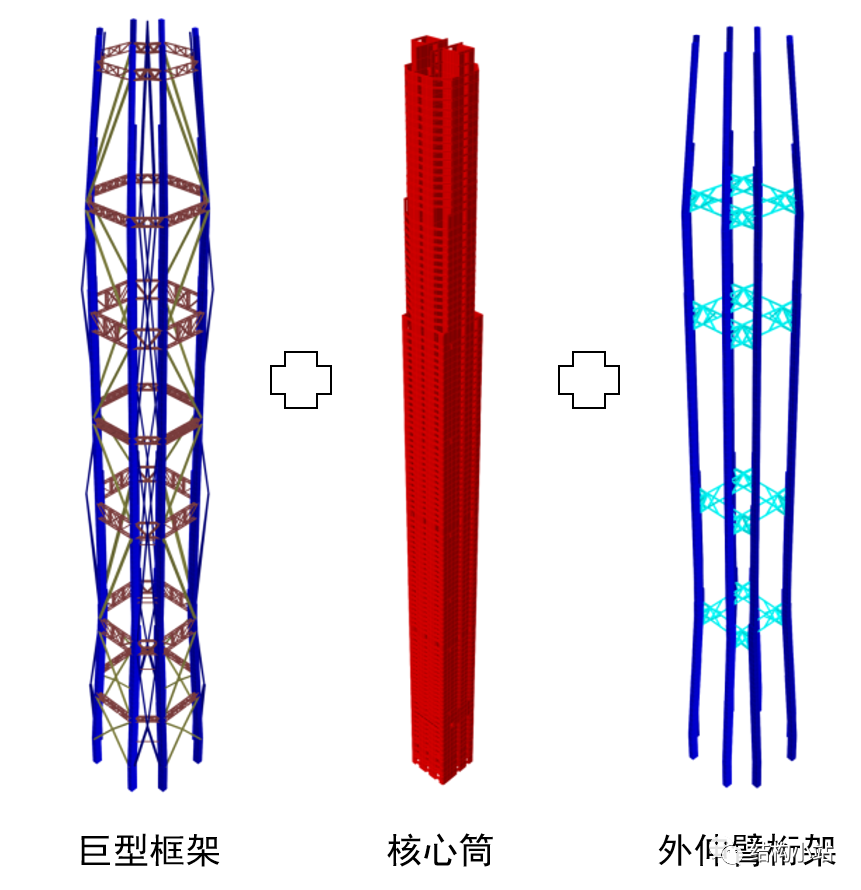

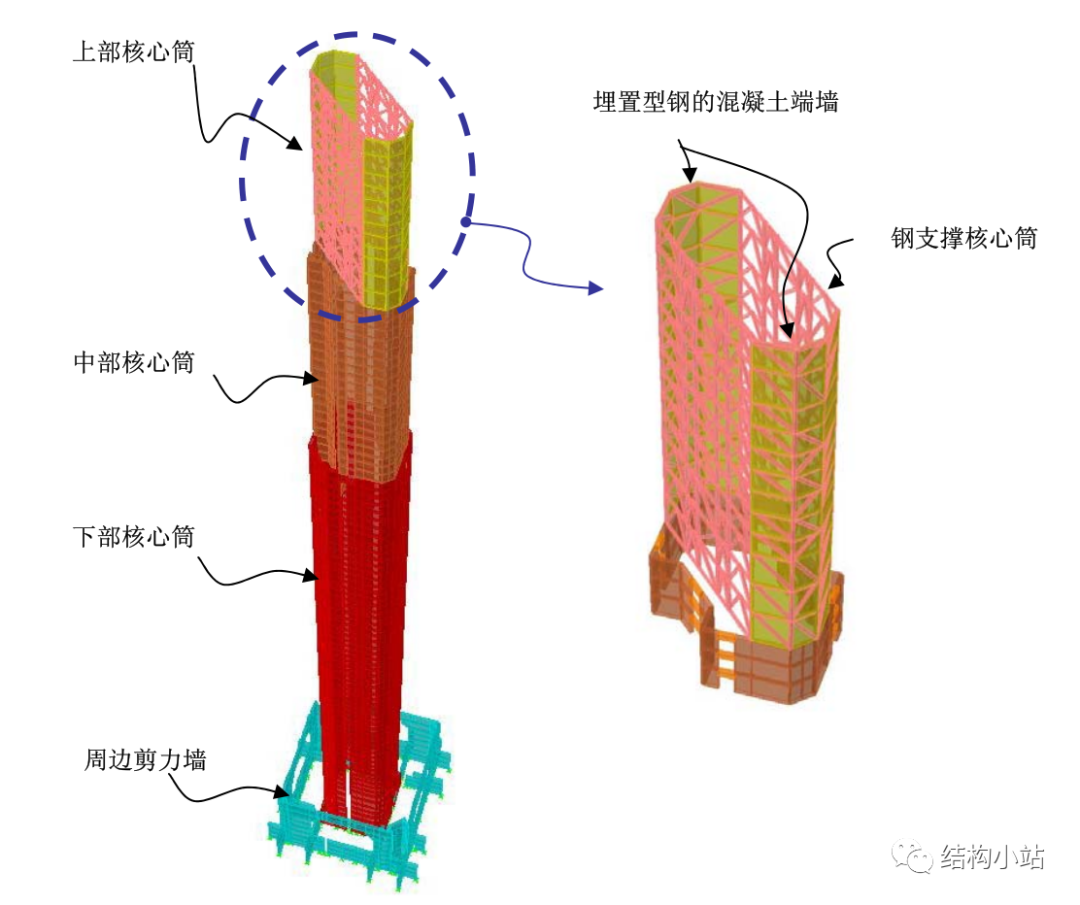

The structural system adopts “mega frame core tube boom truss”.

You may all know these famous super high-rise buildings such as Shanghai center, Shanghai world financial center and Taipei 101.

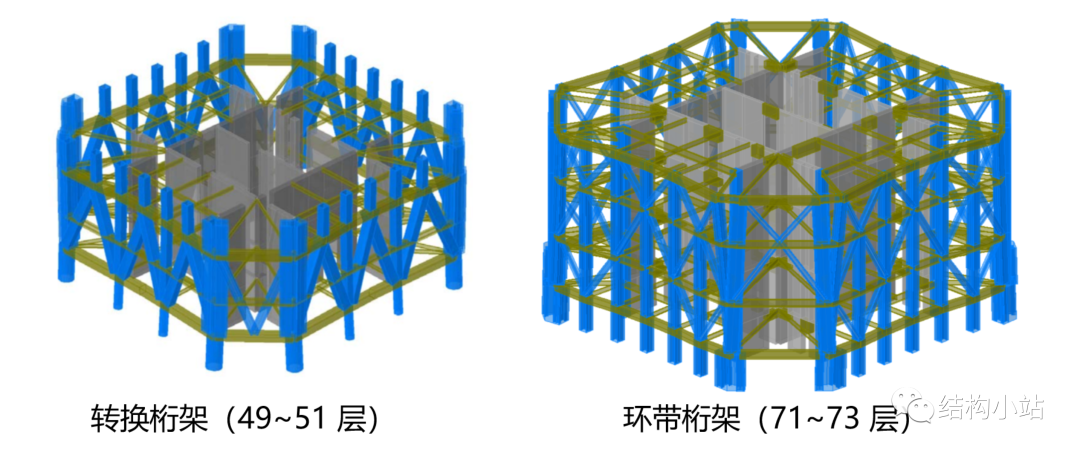

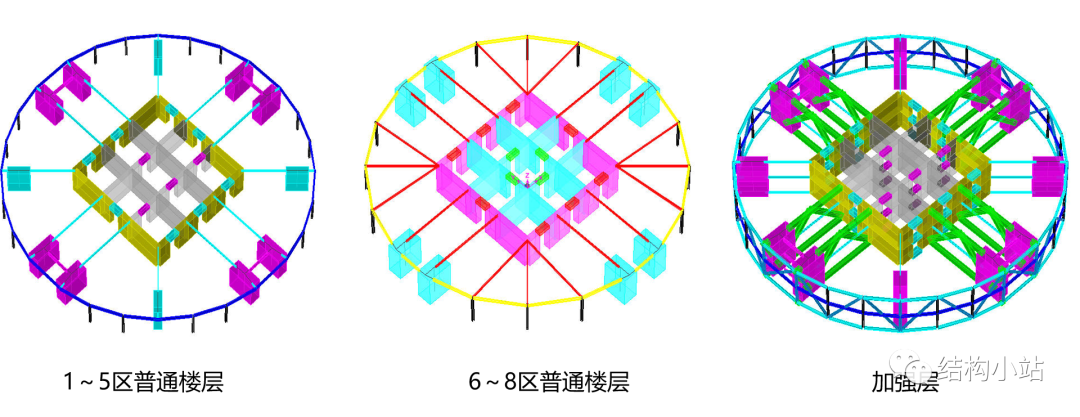

At the same time, a one storey radial truss is also set in the reinforcing layer to transfer the load of the curtain wall cantilevered on the outside to the mega frame.

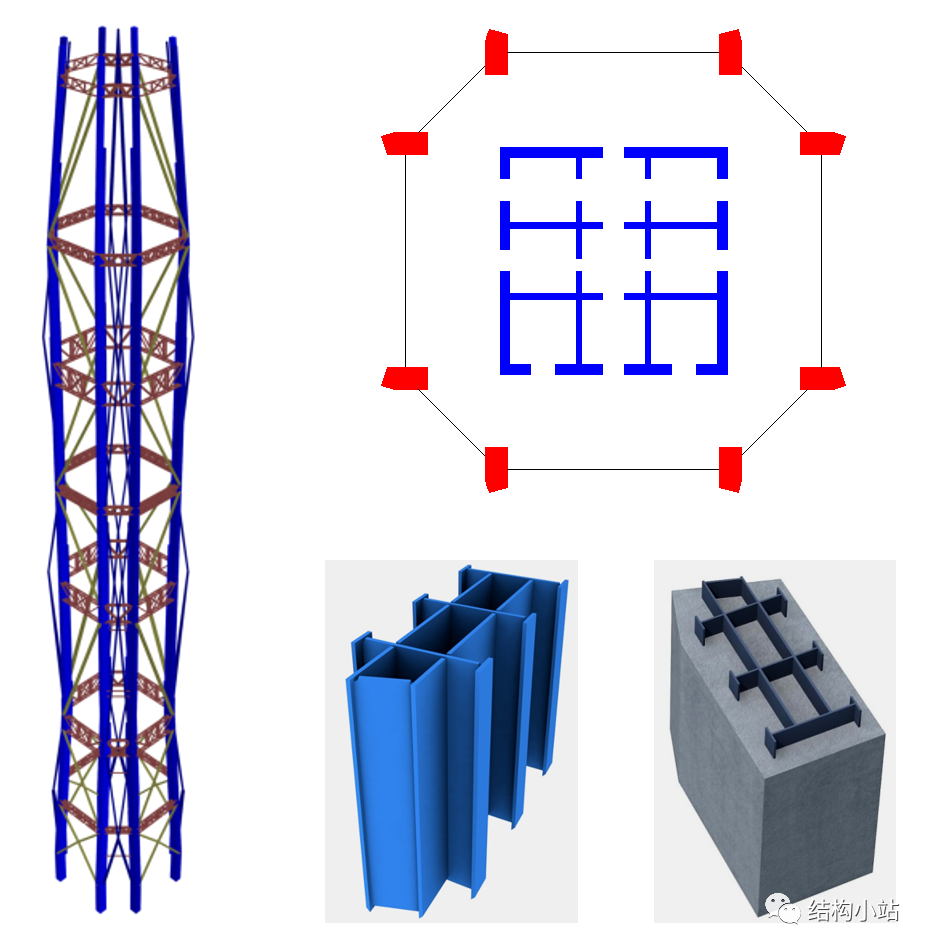

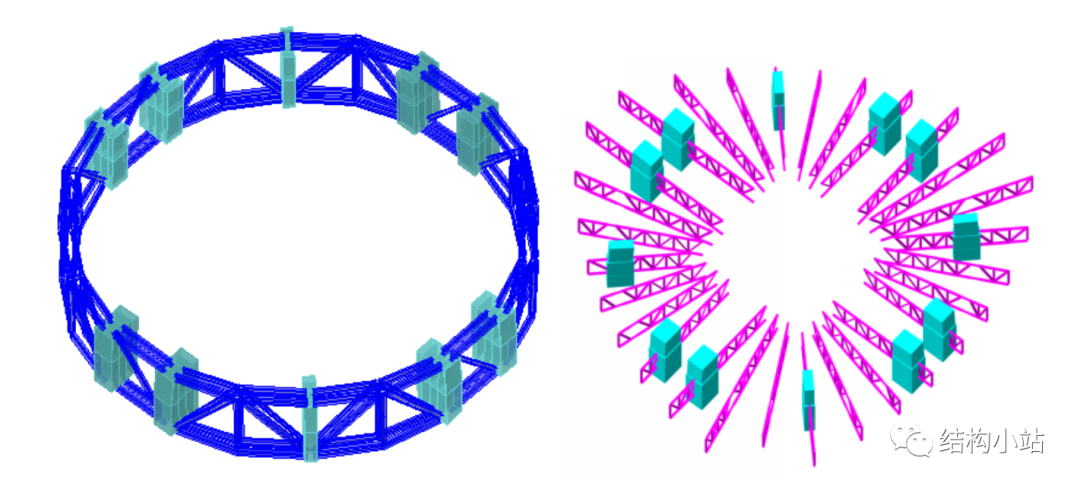

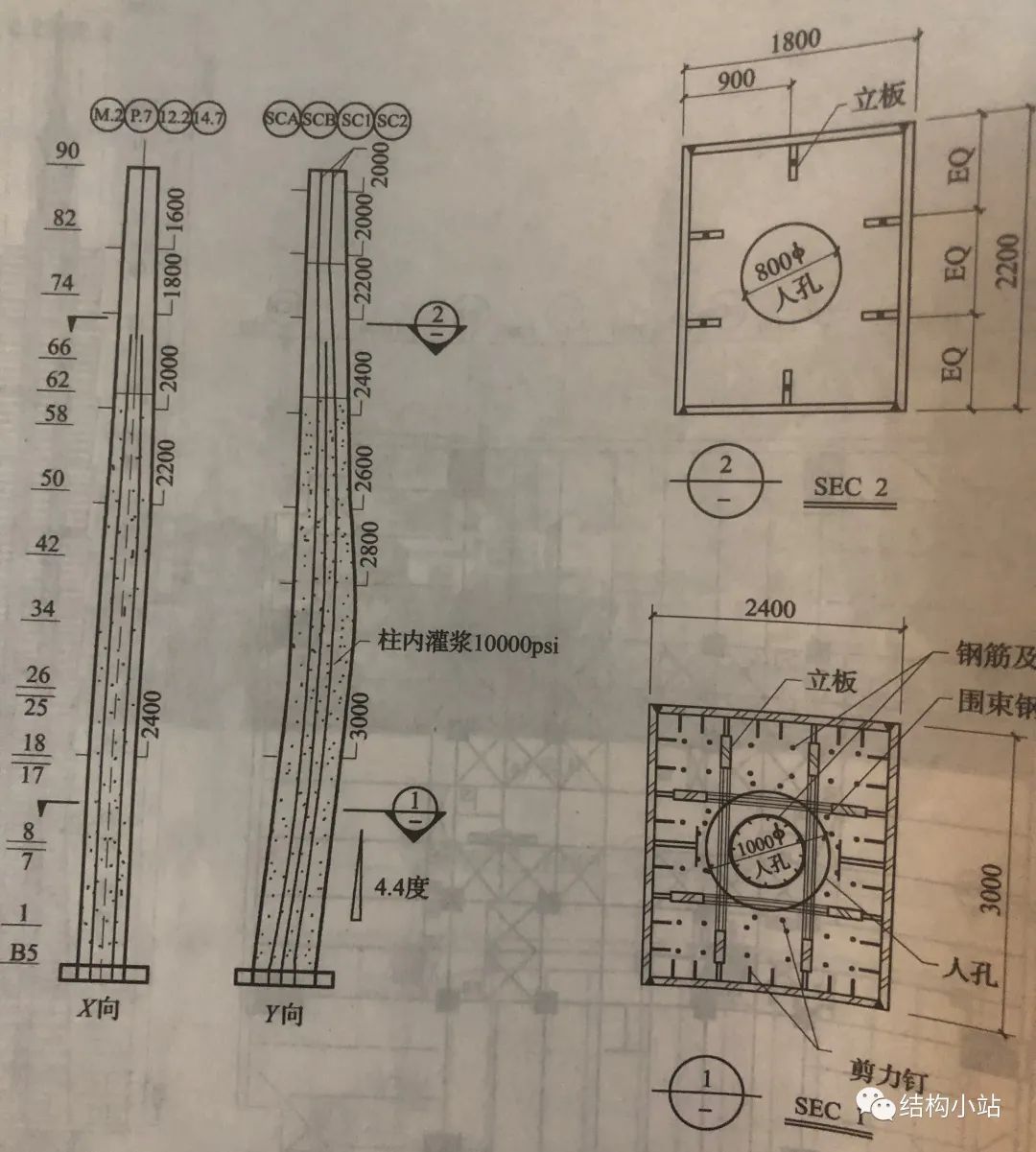

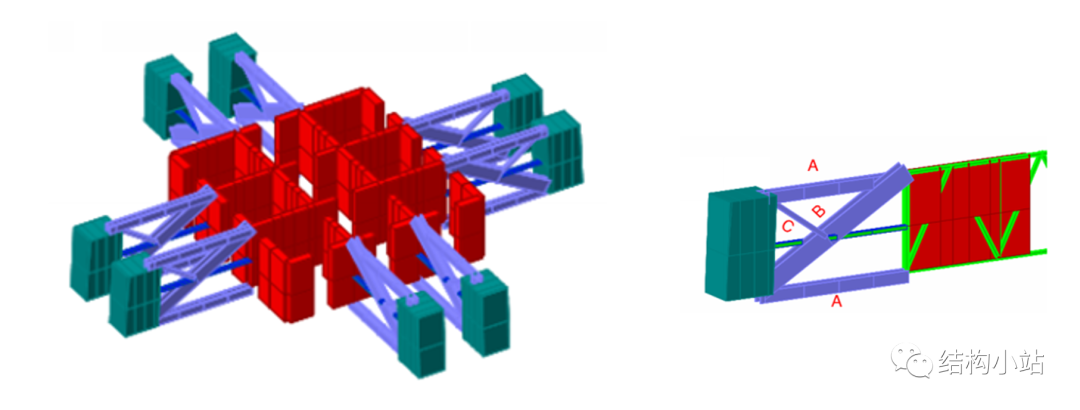

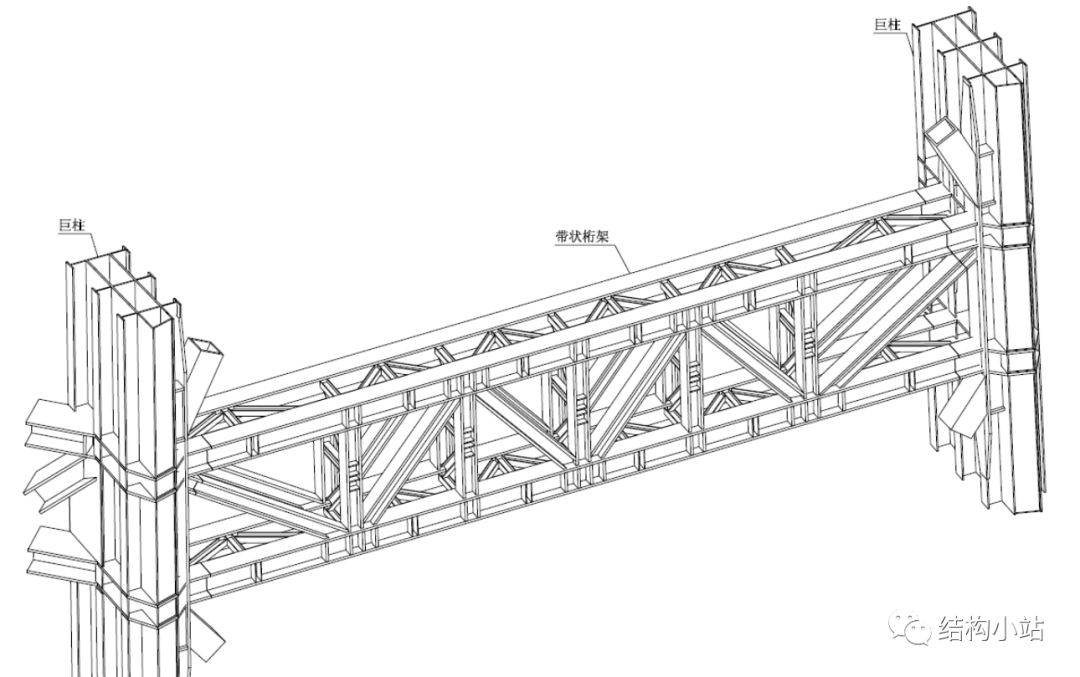

▲ schematic diagram of ring truss the giant column adopts SRC column with special-shaped section, and the column adopts King shaped steel.

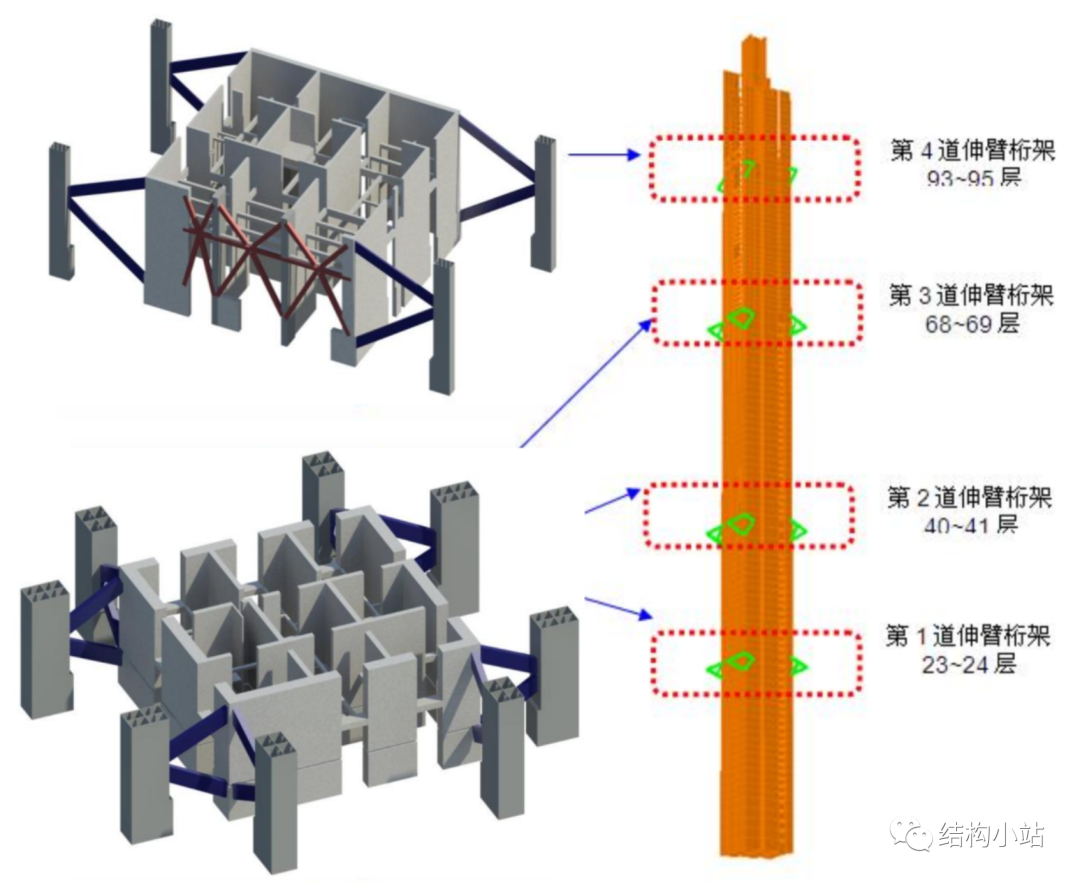

▲ the form of steel skeleton in giant column (@tt) the mega frame composed of giant column and ring truss is connected with the core tube through 6 outrigger trusses, so that the mega frame can work effectively with the core tube.

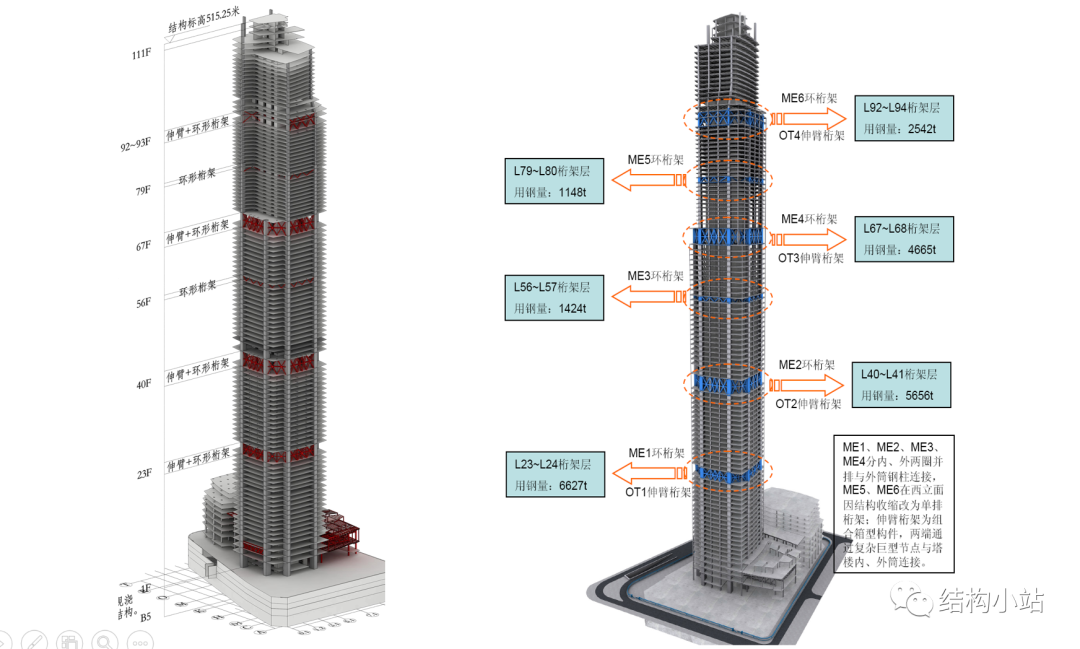

Six outrigger trusses are located at the equipment floor of zones 2, 4, 5, 6, 7 and 8 respectively.

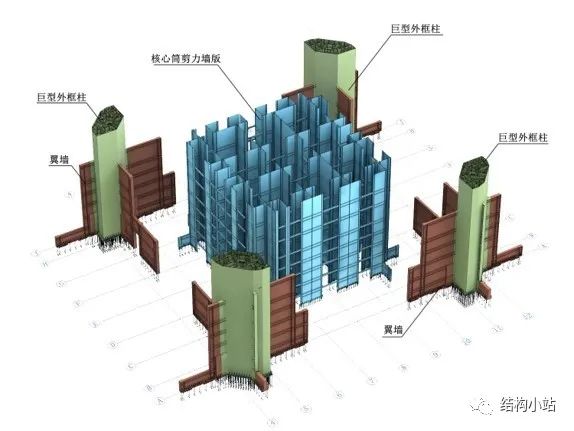

The peripheral mega frame is formed by ring truss and giant column.

China has built the top ten super high-rise buildings (@CTBUH).

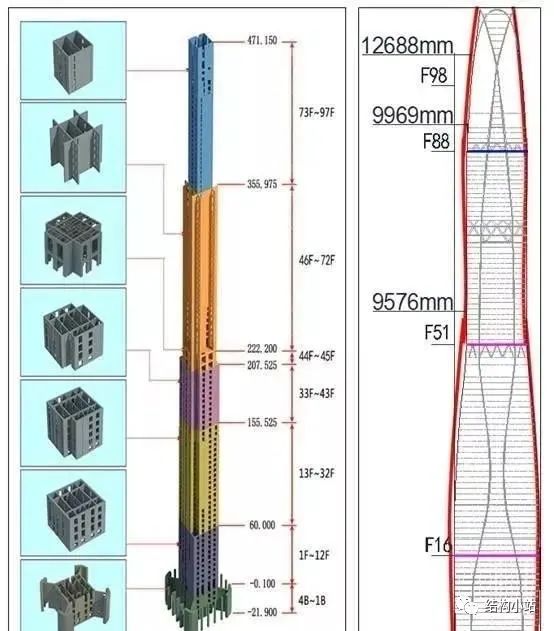

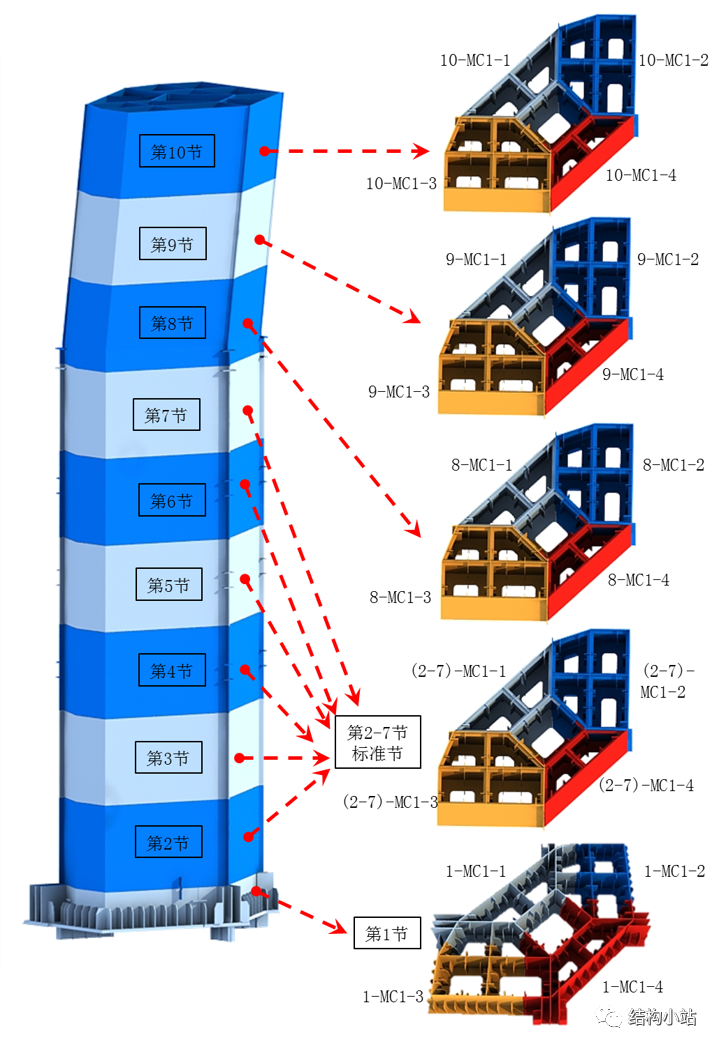

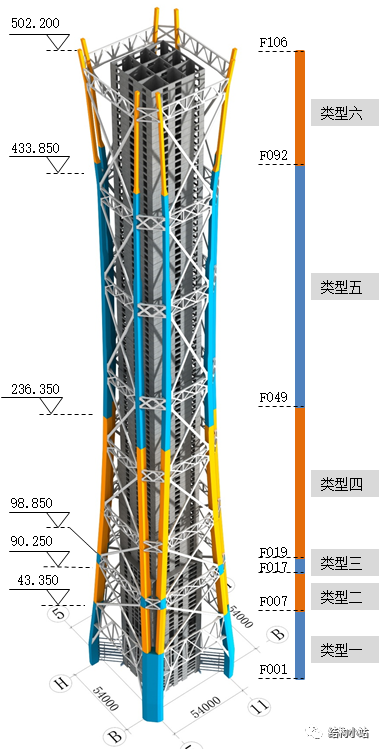

The mega frame is composed of 8 giant columns, 4 corner columns (only arranged in the basement and areas 1-5), 8 two-story ring trusses (located on each reinforcing floor).

The steel content is 4% ~ 6%, as shown in the figure below..

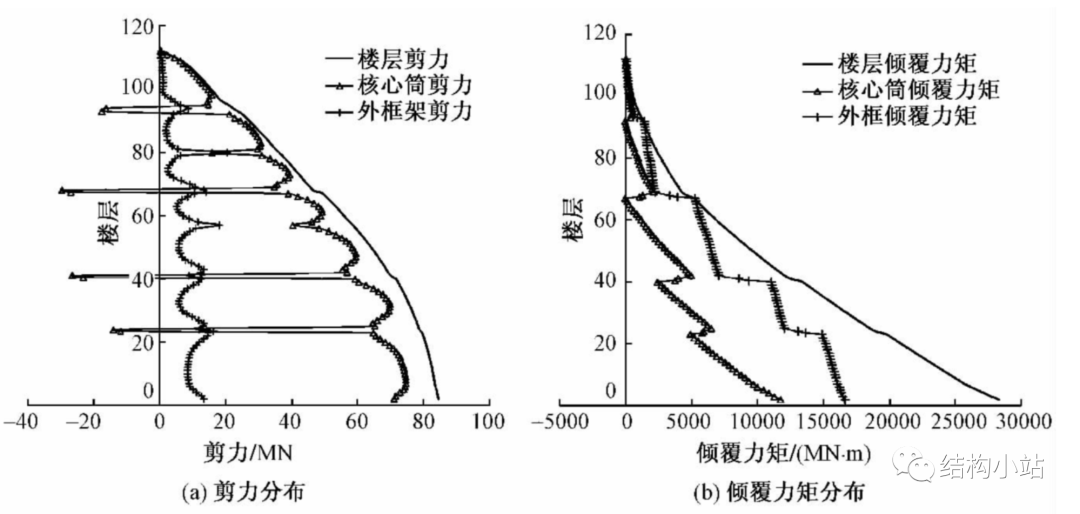

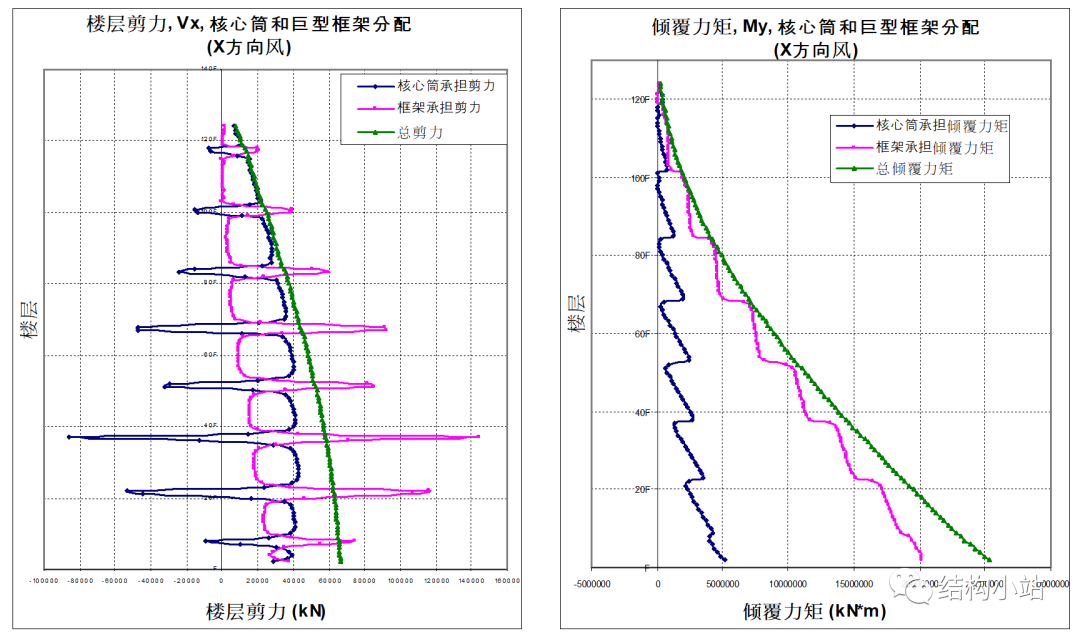

Under the action of horizontal load, the core tube bears about 48% of the base shear and 22% of the overturning moment, and the mega frame bears about 52% of the base shear and 78% of the overturning moment.

Compared with the single annular truss, its restraint effect on the giant column is basically unchanged, and the torsional stiffness of the annular truss is increased.

The 55m high home insurance building in 1885 is known as the first skyscraper in history.

The third round of application of ghda global Habitat Design Award was opened ↑ in 1883, the word “skyscraper” first appeared in the article of American architect and architecture news.

After more than 20 years of development and construction, China’s super high-rise buildings have also achieved rapid development.

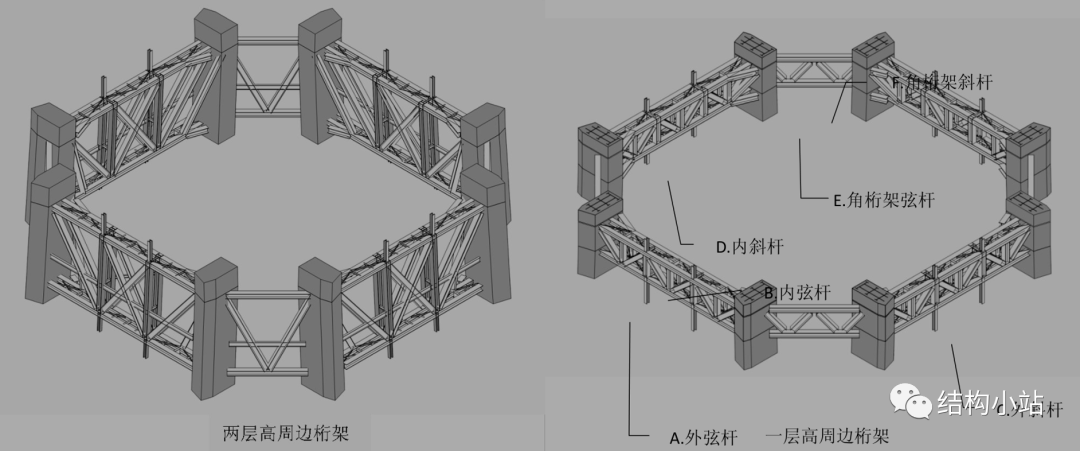

Six two-story outrigger trusses and eight box ring trusses are arranged in eight equipment.

So do you know how the structures of these tallest super high-rise buildings in China are designed? Let’s follow Xiaobian to see how China’s tallest super high-rise building is designed.

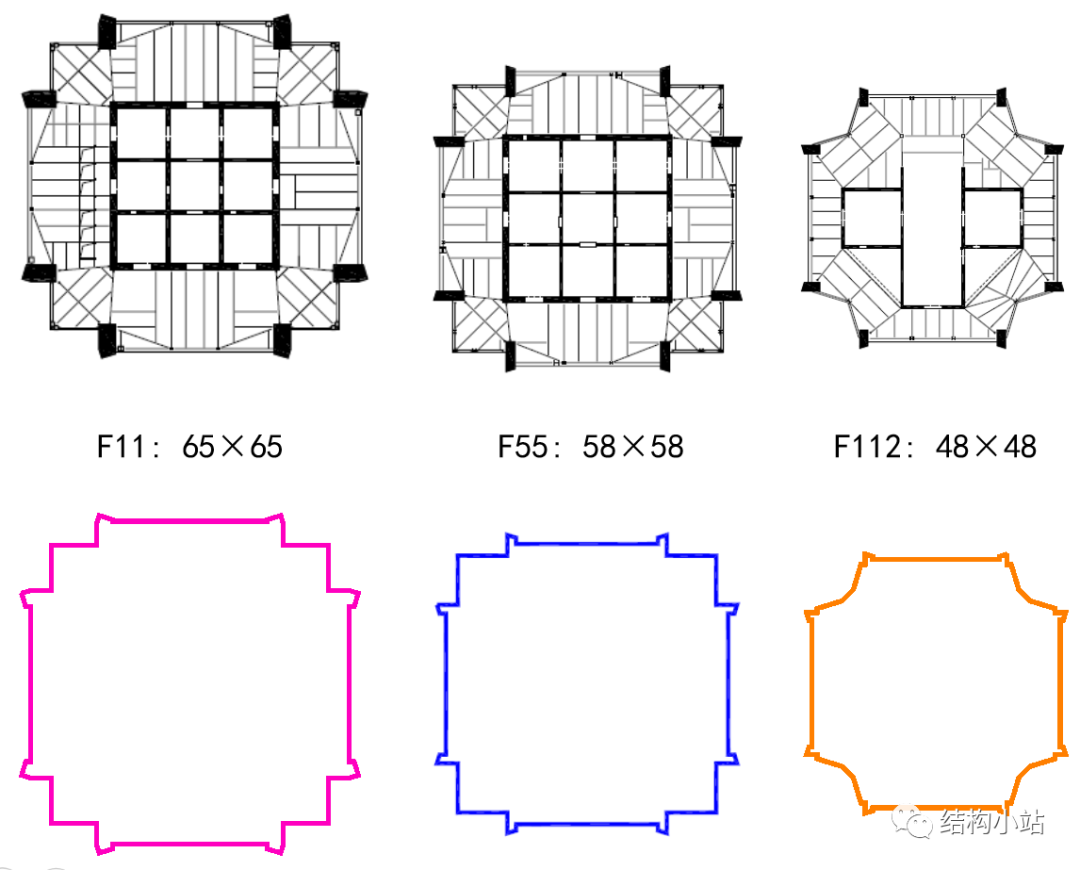

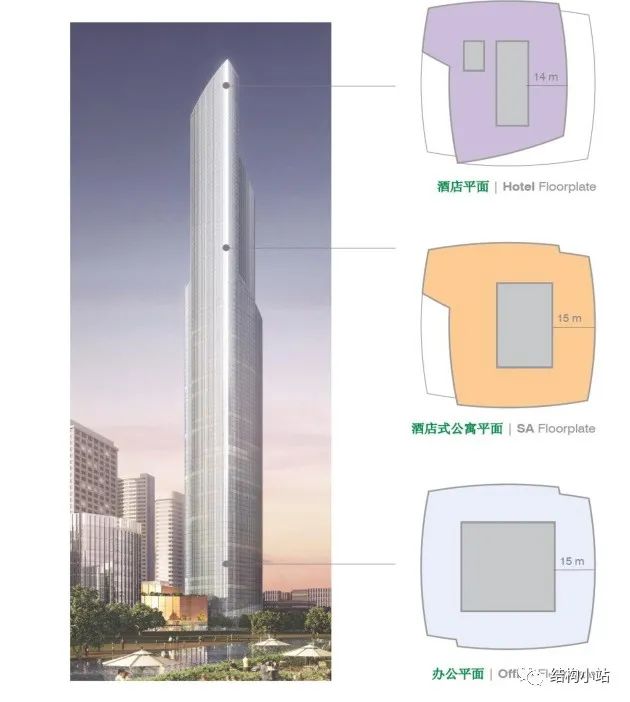

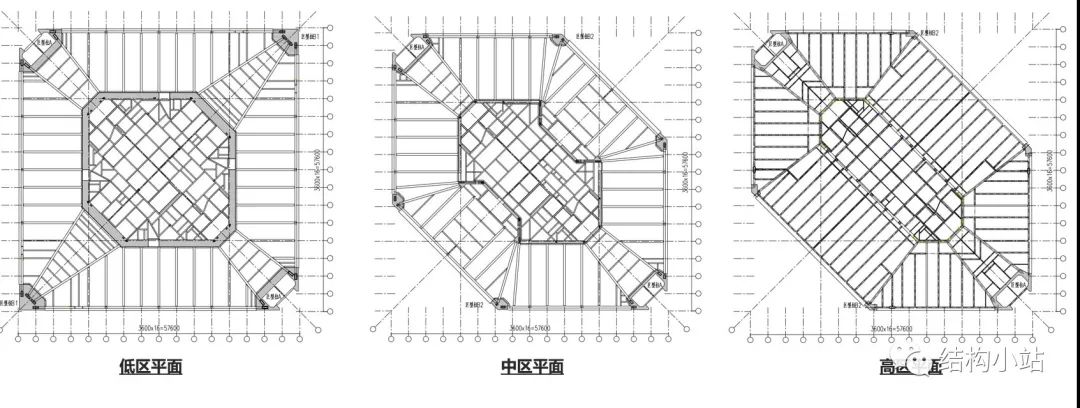

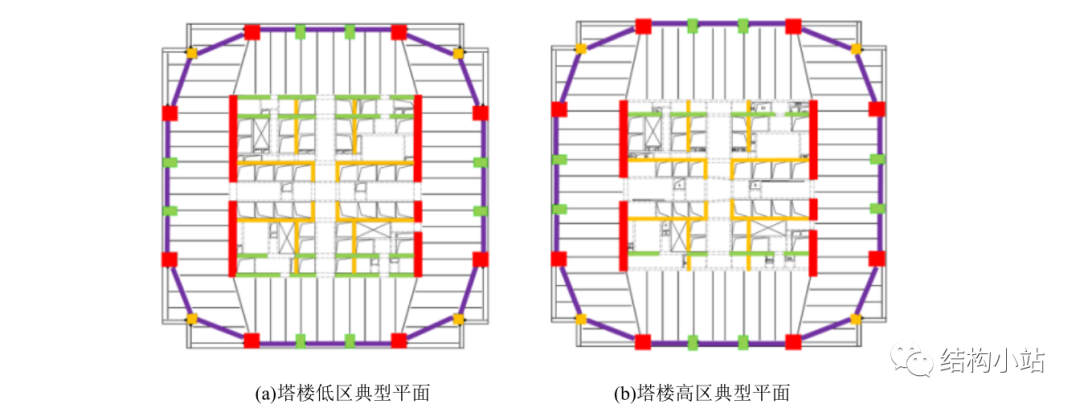

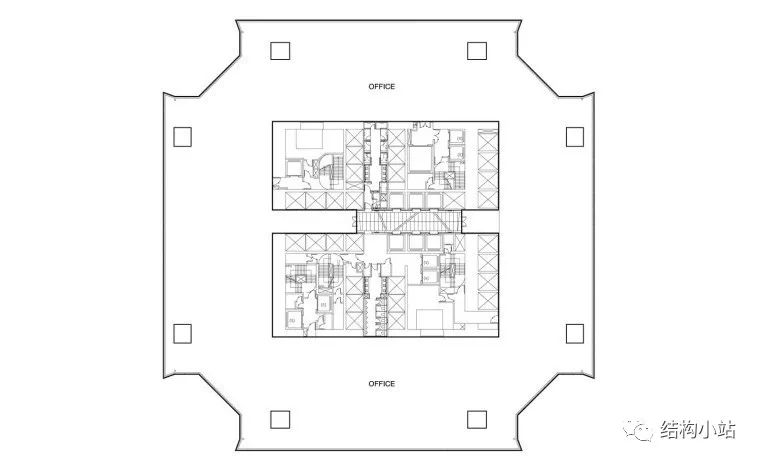

▲ plane size the building plane is about square, the corner is cut inward, the plane size of the bottom is about 65x65m, and the plane size is gradually retracted along the height.

According to the latest statistics of CTBUH, China accounted for 11 of the top 20 super high-rise buildings built in the world by 2021.

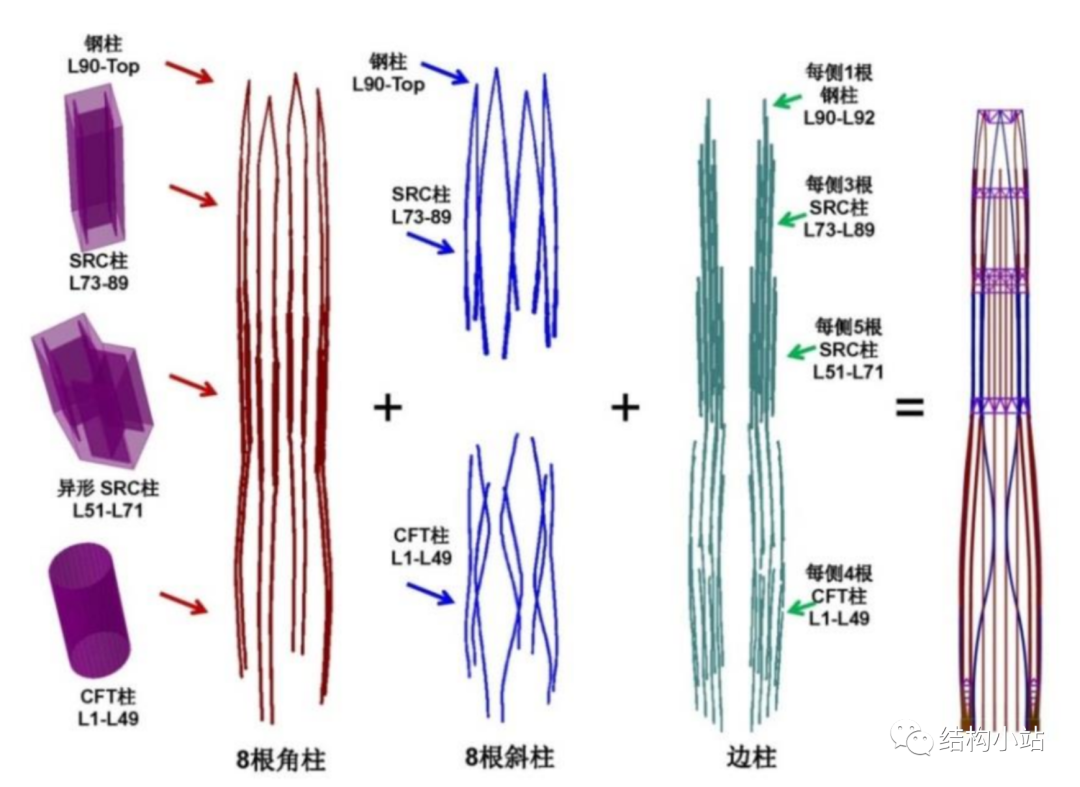

The maximum section size of the giant column is 6525x3200mm, and the closing to the top is 3120x1400mm.

▲ schematic diagram of structural system composition (@tt) the annular truss is a double box space truss.

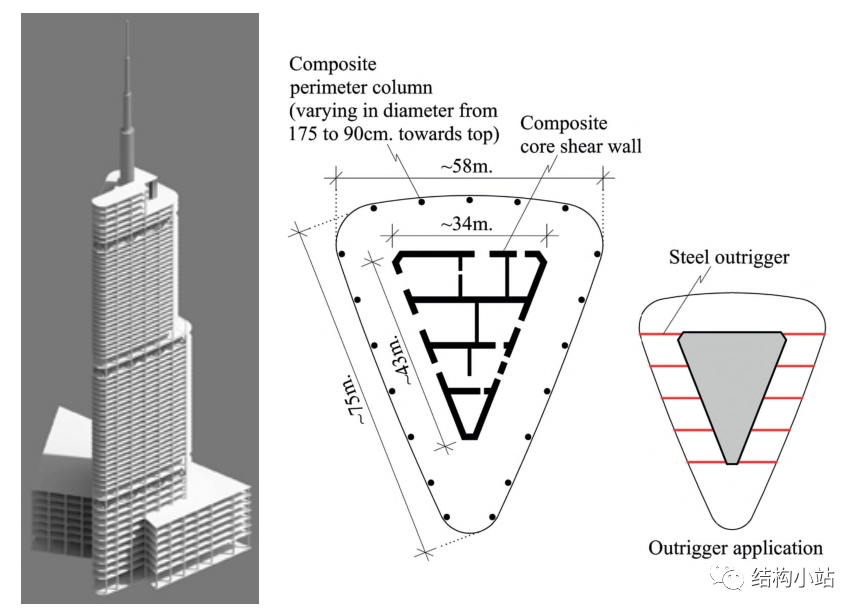

At present, it is the tallest building in Shenzhen, the second tallest building in China and the fourth tallest building in the world.

The lateral force resisting system of the tower is a “mega frame core tube outrigger” structural system.

(3) the schematic diagram of the torsional rise of the Shanghai central plane.

▲ giant column layout (@tt) the maximum section size of giant column is 3.7×5 3M, 1.9×2 at the top 4m, the giant columns in zones 1 ~ 6 adopt King shaped steel frame, and zones 7 ~ 8 adopt Japanese shaped steel frame.

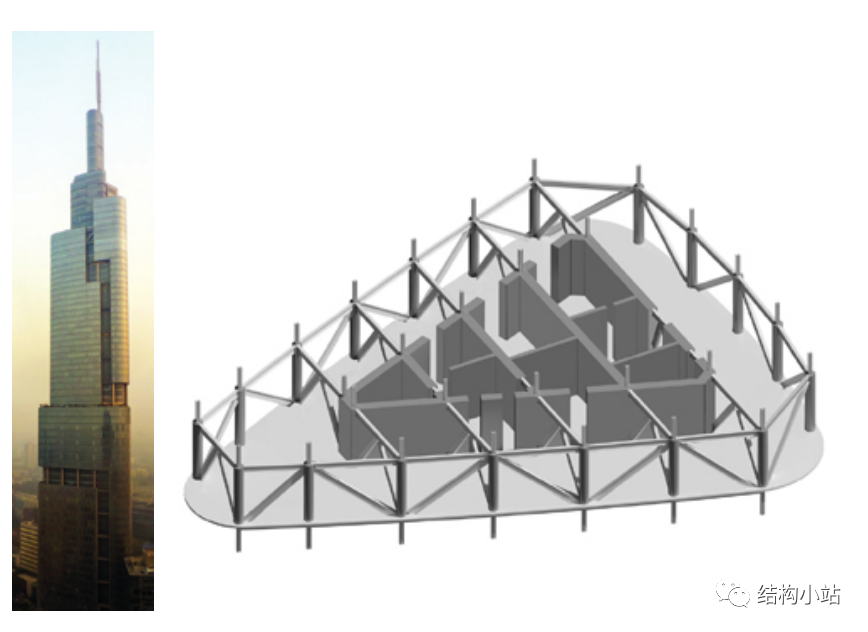

The distribution ratio of shear and overturning moment for mega frame and core tube (@tt) – Shanghai center 2 Architectural design of Shenzhen Ping An financial center: KPF & CCDI structural design: TT & CCDI structural system: mega frame core tube outrigger truss Shenzhen Ping An financial center, with a building height of 599.1m, a structural height of 562.2m, 115 floors above the ground and 5 floors underground, was officially completed in 2017.

Shanghai Center Tower buildings were officially completed.

The structural system is similar to the Shanghai center.

Compared with the single ring belt truss, its section is smaller and the connection with the giant column is more convenient, as shown in the figure below.

As the building height keeps rotating and rising and even shrinking, the torsion degree of each layer is about 1 degrees, which reversing 120 degrees.

The development of super high-rise buildings in China began in the 1990s.

The development of cast iron industry and the successful installation of electric elevator mark the advent of the era of skyscrapers.

The vertical partition map of Shanghai center is a triangular shape with a chamfered angle.

The Shanghai center is second of the world’s tallest, second only to Harry Fatah, the world’s tallest Dubai (828 m).

The mega frame is composed of 8 giant columns, 7 ring trusses and giant diagonal braces, and is equipped with 4 two-story boom trusses to coordinate the interaction between the mega frame and the core tube.

It can be seen that the mega frame bears the main horizontal shear force and most of the overturning moment.

Eight giant columns are connected with the core tube through six two-story outrigger trusses, so that the core tube and the outer frame can deform harmoniously and jointly resist lateral loads.

The girdle truss has two double girdle trusses on the facade and a single truss at the corner.

▲ schematic diagram of ring truss and radial truss (@ TT) ▲ schematic diagram of outrigger truss (@ TT) the giant column adopts SRC giant column.