The reinforcement straightening process of winch is prohibited, which is well understood.

The key words are “simple production on site (mixing mortar at the construction site and making reinforcement protective layer cushion block by cutting and forming)”.

The process is backward and the safety is difficult to be guaranteed.

For example, when the thermal insulation materials catch fire frequently during waterproof construction, the self-adhesive and polymer adhesive waterproof coiled materials will be gradually popularized and used.

5.

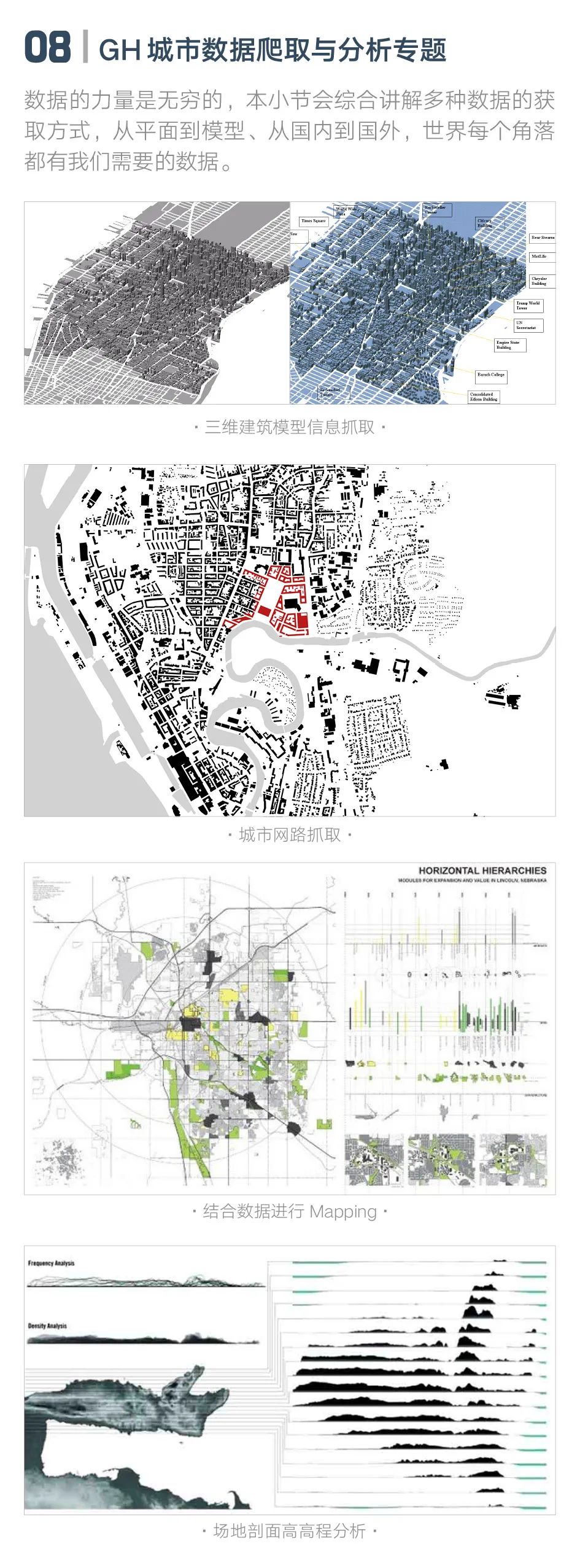

The document involves housing construction engineering and municipal infrastructure engineering, which is divided into three dimensions: construction technology, construction equipment and engineering materials; We analyze and interpret the direction of housing construction.

Manual excavation is limited to the drilling of foundation piles; if one of the following two conditions is met, it shall not be used: (1) areas with rich groundwater, air pollutants in the hole exceeding the standard, soft soil layer, quicksand and other adverse geological conditions; (2) areas accessible to mechanical drilling equipment.

The limiting condition is that it shall not be used for waterproof works near underground confined spaces, poorly ventilated spaces and flammable materials.

In fact, we have not seen the practice of exterior wall facing bricks for construction projects, especially high-rise residential buildings for many years, let alone the frequent accidents of exterior wall brick falling off in the past The falling off accident of external wall insulation layer is not uncommon; 6.

1、 Construction process construction process involves 6 contents: key words construction process 1.

It is recommended to standardize the production of professional equipment, so it is not prohibited to make mortar cushion block or cushion block “Own problems” , there are requirements for the selection of manufacturing process; 2.

Construction media ID: jianzhong001 how to understand the document “prohibit the use of mortar cushion blocks” issued by the Ministry of housing and urban rural development? At the beginning of July this year, the Ministry of housing and urban rural development issued the catalogue of construction processes, equipment and materials for housing construction and municipal infrastructure projects (the first batch) (Exposure Draft), which aroused thousands of waves on the Internet, such as “mortar cushion block is prohibited”, “hot melt coiled material construction is not allowed to be used” and “material hoist is out of the historical stage” Wait, the speech is rampant, the good and the bad are mixed! The only purpose of the exposure draft of the “Catalogue” issued by the Ministry of housing and urban rural development is the word “safety”, so we should start from the perspective of “reducing construction safety risks and improving safety production level”.

It is well understood that the safety of operation conditions is difficult to be guaranteed.

However, in the actual construction site, this process is limited by operation and applicable conditions, and has been rarely used, such as sleeve cold extrusion connection, rolling straight thread sleeve connection and other machinery The connection process has been mature; 4.

The limiting condition is that it shall not be used in projects where the pasting height of exterior wall facing bricks is higher than 15m.

“Manual hole digging pile” The process has not been completely prohibited.

If there is infringement, please contact to delete!) long press the QR code to pay attention to us ▶▶▶。.

Then, the floor waterproof and roof waterproof of large-area open can still be used, but with the on-site opening Fire is easy to cause fire.

The use of asphalt waterproof coiled materials constructed by open fire hot melting method is limited because it is prone to fire accidents.

It is forbidden to simply make reinforcement protective layer cushion block process on site.

The use of cement mortar to paste exterior wall facing bricks is limited because of the potential safety hazard of falling off.

At present, most construction sites have the reinforcement straightening process of ordinary reinforcement straightening machine and NC reinforcement straightening cutter; 3.

(source: integrated in the network, the pictures and copyright belong to the original author.

The use of manual flash butt welder for reinforcement welding is limited, provided that it is in a non fixed professional prefabrication plant (yard) Or reinforcement processing plant (yard) In short, this process can still be used for rebar connection with a diameter greater than or equal to 22mm in the rebar batch production workshop or rebar with a diameter less than 22mm.