1、 Responsibilities and obligations of main participating units: construction unit: send the design documents of prefabricated building construction drawing to the review organization for review

.

When the construction drawing design documents involve important changes related to structural safety and use function, they shall be sent to the original review organization for review

.

According to the characteristics of prefabricated building construction, the cost of safe production and civilized construction measures should be fully allocated

.

Do a good job in the coordination of design, construction general contracting, supervision, component production and other parties in the construction progress and work cooperation

.

If the construction project is under supervision, the construction unit shall entrust the supervision unit to supervise the production of precast concrete components and pay the corresponding supervision fees

.

Establish the corresponding work system, organize all parties involved in the project to carry out the acceptance of the first piece of precast concrete component production and the first section of on-site installation

.

Batch production or subsequent construction can be carried out only after the acceptance is qualified

.

Design unit: the construction drawing design documents shall strictly comply with the regulations on the compilation depth of prefabricated architectural design documents

.

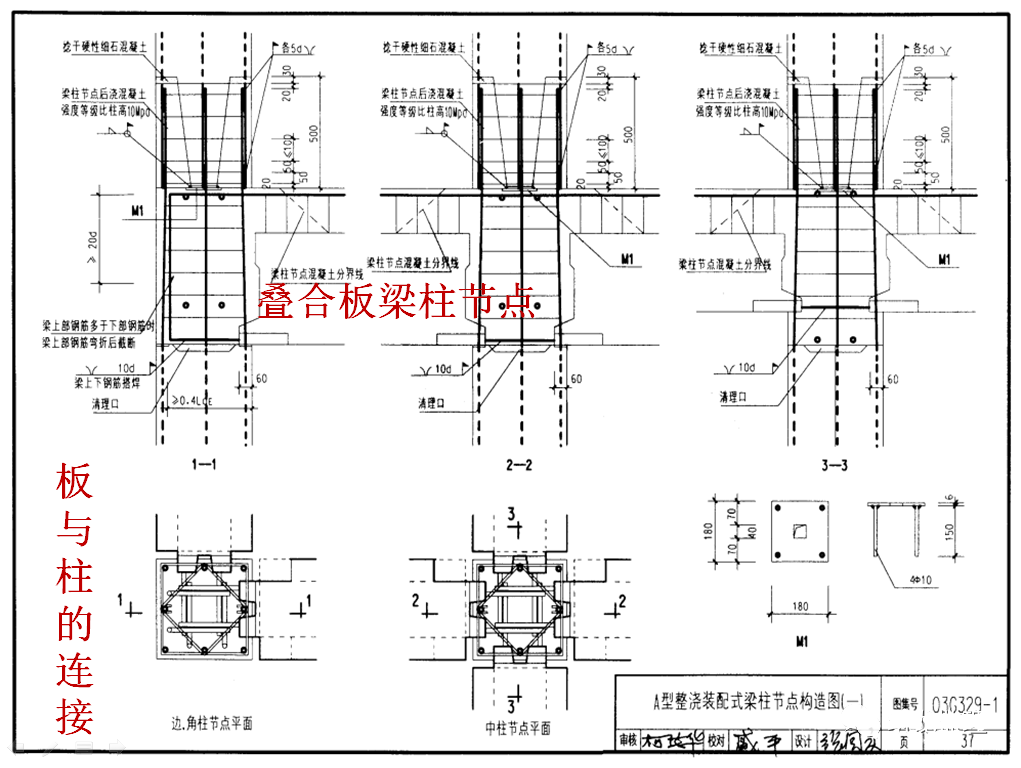

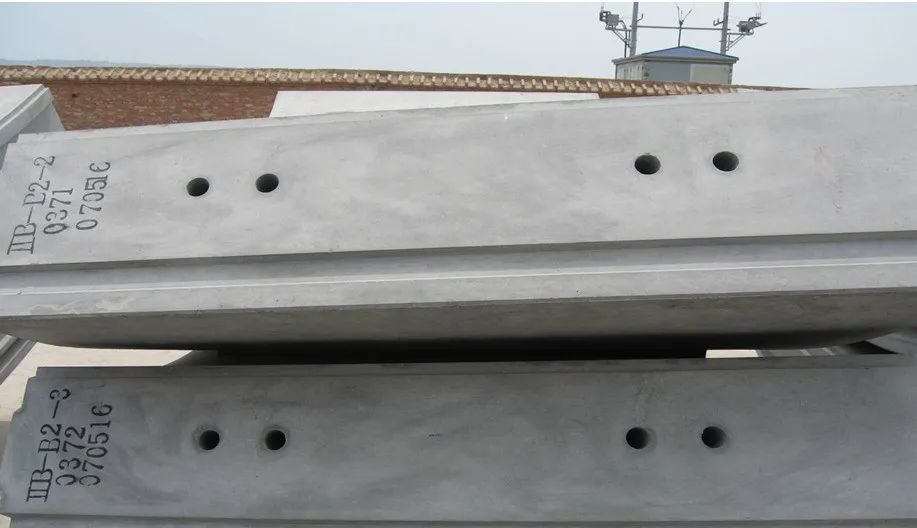

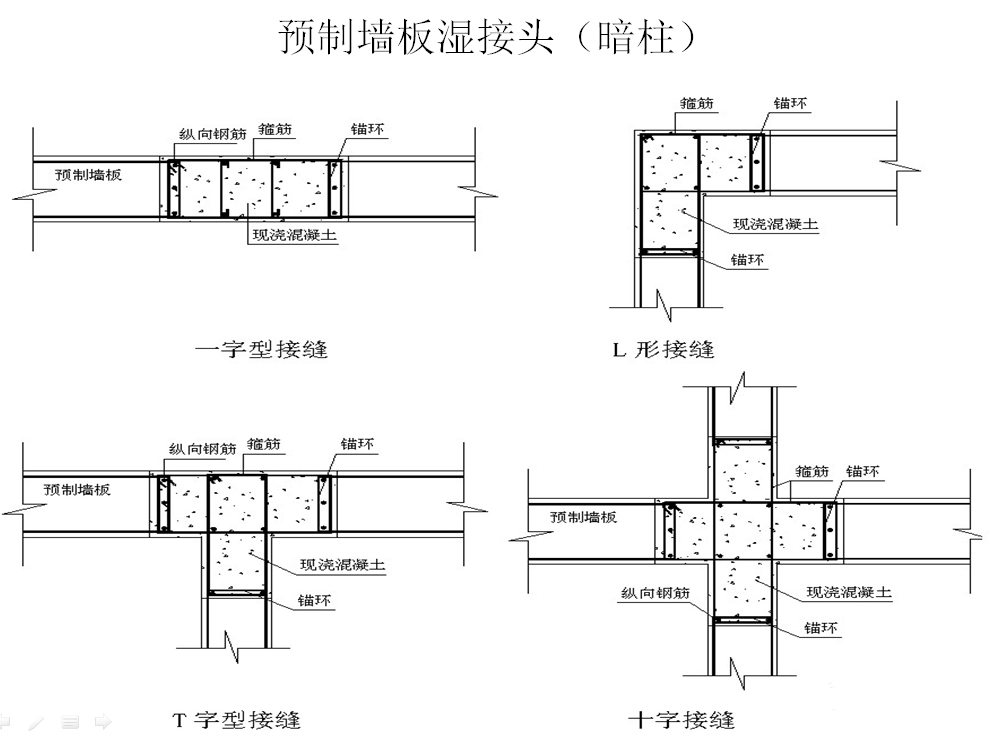

In the construction drawing design documents, the structure type, prefabricated assembly rate, prefabricated component position, prefabricated component type, the construction method between prefabricated components and between prefabricated components and main casting shall be specified, and the structural design specification shall be prepared

.

Put forward special design requirements for possible major risks

.

(now some prefabrication yards are designed to be approved by the designer) the design unit shall, together with the construction unit, fully consider the factors such as the lifting points of components, the embedded parts of tower crane and construction machinery attached to the wall, the scaffold tie and so on, so as to facilitate the production and subsequent construction of components, and put forward the measures to ensure the quality and safety in the construction process (including checking the bearing capacity of the component stacking yard)

.

The design unit shall do a good job in the construction site Service, and assign a special person as the person in charge of on-site service

.

When there are important changes related to the structure safety and use function, the design unit shall strictly check and remind the construction unit to send the modified documents to the original review organization for review

.

Construction unit: it shall pass the external audit of safety production management system according to the code for safety production management of site construction (dgj08-903-2010)

.

Prepare the quality and safety special plan of prefabricated building construction in time, and go through the approval procedures according to the regulations

.

For the special construction operation platform for prefabricated buildings with new materials, new equipment and new technology, as well as the protective facilities for high altitude and edge operation, the special scheme shall be verified by experts according to the regulations

.

The construction general contractor shall clarify the responsibility limits of the general contractor and the sub contractor in the sub contract for the cross construction, so as to effectively implement the safety responsibility, and coordinate and urge the sub contractors to cooperate with each other, so as to effectively implement the contents of the construction organization design and special scheme

.

The subcontractor shall obey the general construction scheduling arrangement of the general contractor, especially the hoisting subcontractor shall strengthen the coordination with other subcontractors

.

Operators engaged in the hoisting of prefabricated components on site shall hold the certificate of special type of work for construction work at height

.

The construction unit should vigorously promote the application of BIM Technology to meet the quality and safety requirements of process, process, facilities and equipment

.

The construction general contractor shall, according to the characteristics of component yard setting, installation and use of equipment and facilities, and discontinuous construction caused by hoisting, prepare safe production and civilized construction measures, and strictly implement them

.

Supervision unit: the supervision unit shall strictly review the approval and expert argumentation of the special construction scheme, prepare the operable supervision implementation rules according to the special scheme, clarify the key links, key parts and side station inspection requirements of supervision, and keep the image data for the key links and side station of key parts

.

When the on-site supervision is implemented in the production of prefabricated components, the supervision unit should earnestly perform the relevant supervision responsibilities, implement the raw material acceptance, inspection, concealed project acceptance and inspection batch acceptance, and prepare the on-site supervision evaluation report

.

The key points of site supervision daily on-site inspection should include the preparation work before lifting, the arrival of management personnel in the lifting process, the employment of operators with certificates, the performance of lifting supervisors, the implementation of protective measures and relevant auxiliary facilities for edge operation, etc

.

Production unit of prefabricated components: the processing drawing design of prefabricated components shall be reviewed and confirmed by the original construction drawing design unit

.

The production plan of prefabricated components shall be prepared, the quality assurance measures shall be defined, and the approval procedures shall be carried out according to the regulations

.

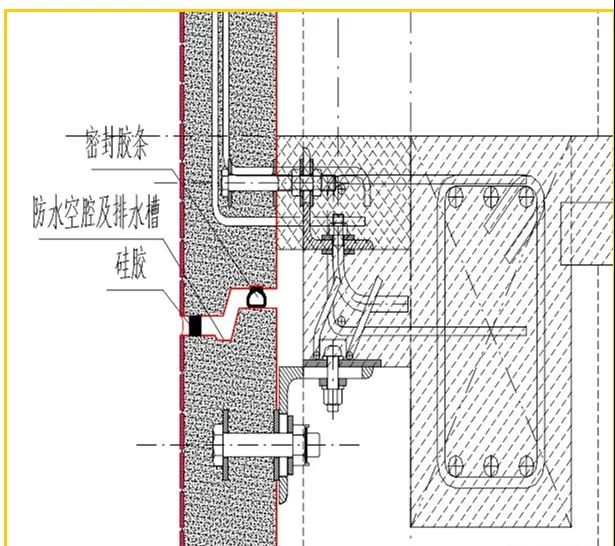

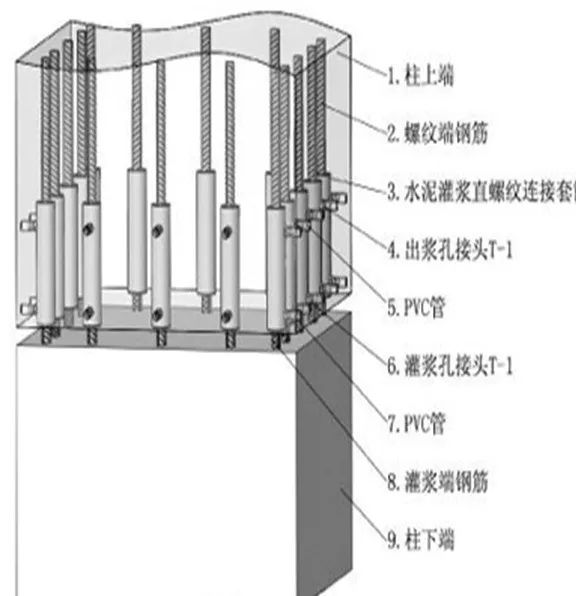

Strengthen the quality control in the production process of prefabricated components, and strengthen the inspection of raw materials, concrete strength, connectors, component performance, etc

.

according to the specifications and standards

.

(including the acceptance, maintenance and strength of the concealed works) the production unit shall mark the qualified prefabricated components, and the components with incomplete marks shall not leave the factory

.

Complete component quality certification documents shall be provided for the delivered components

.

The production unit shall actively cooperate with the supervision unit to carry out relevant supervision work

.

Relevant government supervision organizations: supervision organizations at all levels should effectively carry out supervision according to the requirements of engineering quality and safety supervision and the particularity of the construction of assembled monolithic concrete structure

.

Focus on strengthening spot check and supervision of engineering entity parts and construction behaviors related to engineering structure safety, use function and environmental impact

.

In the project construction preparation stage, it is necessary to focus on the spot check of the scheme approval and demonstration procedures; in the project construction stage, it is necessary to focus on the spot check of the site safety protection, the shift leading of the person in charge and the work of the operators with certificates, so as to supervise the implementation of the quality and safety responsibilities of all parties

.

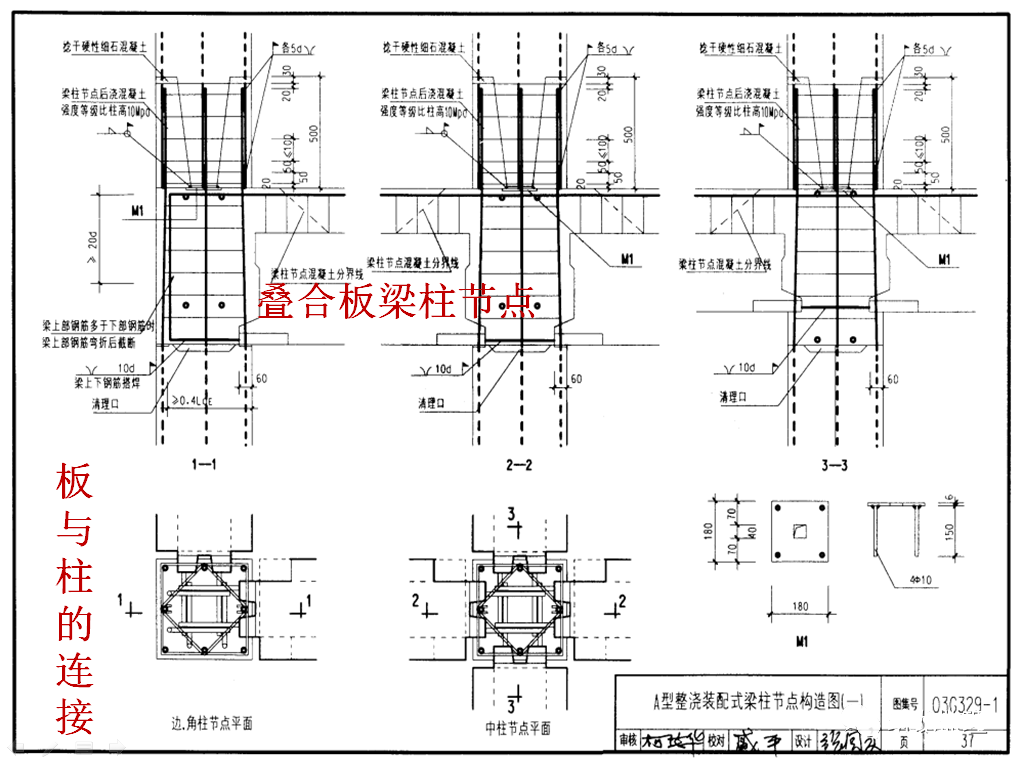

If the supervision organizations at all levels find that there are defects in quality and safety production conditions in the key links such as scheme preparation and approval, stacking, lightering and hoisting of prefabricated components, on-site protection and component connection, structural waterproof and waterproof construction, they shall immediately order partial suspension of construction rectification, if necessary, comprehensive shutdown rectification, and deal with relevant responsible units and individuals according to law

.

2、 The quality supervision production unit of prefabricated components shall carry out the processing drawing design of prefabricated components according to the qualified construction drawing design documents, which shall be reviewed and confirmed by the original construction drawing design unit

.

The production plan of prefabricated components should have quality assurance measures and be approved for production

.

The construction unit shall organize the mass production after the acceptance of the first piece of prefabricated components

.

The supervisor shall carry out on-site supervision for the production of prefabricated components, and check and accept the raw materials, inspection, concealed works and inspection lot

.

The identification of prefabricated components shall not leave the factory without identification

.

At the same time, the manufacturer shall provide complete quality certification documents of prefabricated components

.

The construction unit shall carry out quality acceptance for each batch of prefabricated components entering the construction site, and use them only after passing the sampling inspection by the supervision unit

.

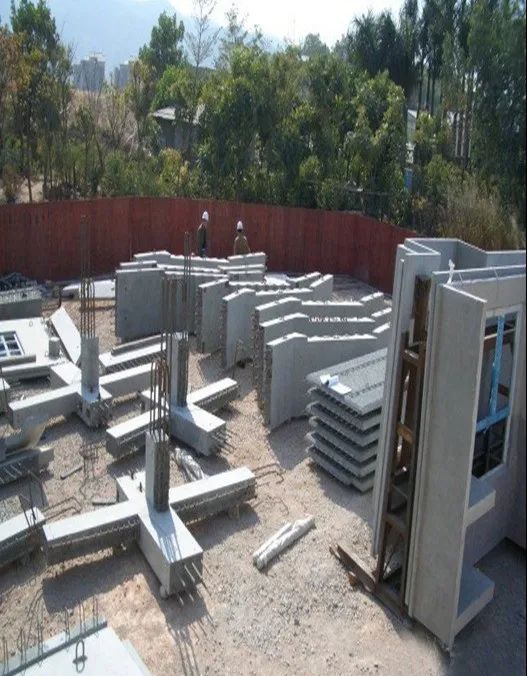

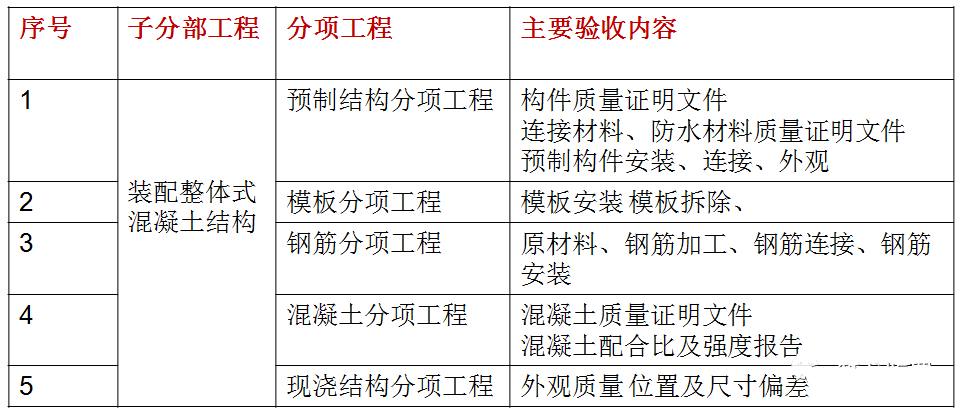

Acceptance content: whether the production unit, component model, production date and quality acceptance mark are marked on the obvious parts of the component; whether the specification, position and quantity of the embedded parts, lifting points, dowel bars and reserved holes on the component meet the design requirements; whether the appearance and size deviation of the component has serious defects that affect the structural performance and installation and use functions; etc.: construction unit and supervision unit At the same time, it is necessary to review the quality assurance documents of prefabricated components, including the concealed acceptance records of lifting points, concrete strength and other related contents

.

3、 Quality Supervision in construction stage 1) construction preparation stage (1) the design unit shall participate in the production technical disclosure organized by the construction unit for the production unit, as well as the design disclosure to the construction unit and the supervision unit

.

When there is a need for component production and site construction, technical support should be given in time

.

(2) The construction unit shall formulate a special scheme involving quality and safety control measures, process and technology control difficulties and key points, and finished product protection measures in the whole process, and pass the audit

.

Special construction scheme: site component stacking, component installation construction, node connection, waterproof construction, concrete cast-in-place construction, etc.

.