We will carry out regional pilot projects of prefabricated green rural housing in Hefei, Lu’an, Guangde and other places.

The Steel Structure Construction Company of China Railway No.4 Engineering Group Co., Ltd.

A few days ago, the reporter saw in the Health Post Station of Feidong County that rows and rows of 3-storey white buildings were decorated in a new way.

In recent years, the company has been deeply engaged in product research and development and technical innovation of steel structure prefabricated buildings, and actively promoted the transformation to building industrialization and greening.

The province has 2 national prefabricated building demonstration cities, 1 national industrial park and 11 national industrial bases; Three provincial demonstration cities for prefabricated buildings, six provincial demonstration parks, and 50 provincial industrial bases, the steel structure processing capacity and production capacity rank first in China.

In principle, other newly-built public buildings with an area of more than 20000 square meters and new residential areas with an area of more than 100000 square meters shall be constructed by assembly.

Since 2000, our province has actively promoted the development of prefabricated buildings.

According to the Action Plan, our province will start to formulate a 75% building energy efficiency standard, and take the lead in implementing it in new civil buildings in cities and towns such as Hefei, Wuhu, Chuzhou, Ma’anshan, etc., which will be fully implemented in 2025.

In three months, a building will be built, with wall panels, stairs, balconies and other “parts” prefabricated by the factory, assembled like an assembled car.

The Action Plan further clarified the scope of prefabricated construction in our province, which is conducive to promoting the innovation of construction methods in our province, improving the development level of prefabricated buildings, and driving the development of building materials, energy conservation, environmental protection and other related industries.” The person in charge said.

By 2025, star rated green buildings in the province will account for more than 30% of new urban buildings.

A building will be built in three months, assembled like an assembled car — energy conservation, environmental protection, efficient construction.

After three stages of initial exploration, continuous promotion and comprehensive development, a relatively complete policy and standard system has been formed, with a certain scale of industrial foundation.

Assembled buildings welcome the development opportunity.

Assembled buildings are rising rapidly, which is causing great changes in the construction industry.

The prefabricated building is an important way to realize green building.

is a national high-tech enterprise integrating steel structure design, production, installation, product research and development, and test detection.

We will continue to strengthen the construction of prefabricated construction industry bases, carry out intelligent construction pilot projects, create prefabricated construction industry alliances, and cultivate three 100 billion level industrial clusters in northern Anhui, along the Yangtze River, and the provincial capital.

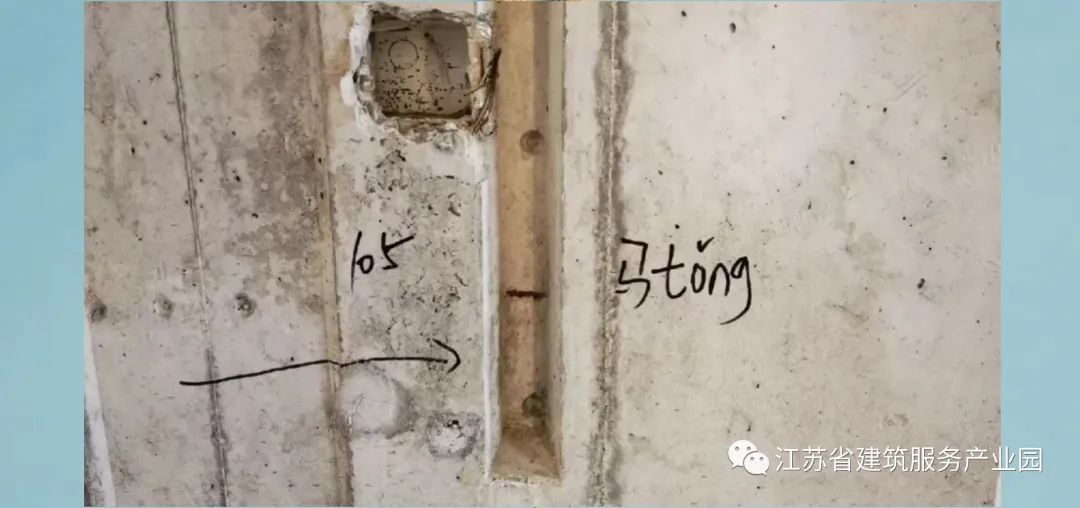

Not only the main structure of the house is fabricated steel structure, but also the sewage treatment station, septic tank, and outdoor rainwater and sewage finished shaft are all installed in the factory and assembled on site, greatly saving the on-site construction time.

The prefabricated building adopts standardized design, factory production, prefabricated construction, information management and intelligent application, which is the representative of modern industrial production mode, and can effectively improve the construction efficiency and reduce the construction waste discharge.

In order to promote the green and low-carbon development of urban and rural construction, Anhui Province recently issued and implemented the Action Plan for Building Energy Efficiency and Carbon Reduction in Anhui Province, vigorously implementing three major actions in the province, namely, the action to improve the energy efficiency of new buildings, the action to reduce carbon in the operation of existing buildings, and the action to optimize the structure of building energy use, vigorously developing green buildings and prefabricated buildings, and promoting the green and low-carbon development of urban and rural construction.

Zhu Lin, the project manager of Feidong Health Post Station of China Railway No.4 Engineering Group, told the reporter that the project has a building area of about 28000 square meters and a total of 16 single buildings.

Green building refers to a high-performance building that can save resources, protect the environment, reduce pollution, provide people with healthy, applicable and efficient use space, and maximize the harmonious coexistence between human and nature.

Chen Guoquan, a technical expert and senior engineer of the Steel Structure Construction Company of China Railway No.4 Engineering Group, said: “Compared with traditional construction methods, prefabricated buildings have the advantages of shortening the construction cycle, reducing labor dependence, reducing construction dust and noise pollution, reducing construction waste and sewage discharge, which is conducive to promoting the transformation and upgrading of the construction industry, accelerating urban and rural green development, and is becoming an important direction for the development of the construction industry..

Its construction scope covers railway, municipal, subway, housing construction and other fields.

From 2022, new civil buildings in cities and towns will be built according to the green building standards, and large public buildings and government invested public buildings will be built according to the standards of one star and above.

The project has realized the universalization, modularization and standardization of fabricated steel structure buildings, and the assembly rate is up to 90%.

“Before this, our province did not define the scope of implementing prefabricated construction from the scale of the project.

“One floor will be completed in almost half a month, and the whole project will be completed in three and a half months.

The person in charge of the Energy Efficiency Science and Technology Division of the Provincial Department of Housing and Urban Rural Development said that the building energy efficiency standard currently implemented in our province is 65%.

New public buildings and residential quarters will adopt more prefabricated construction – vigorously promote prefabricated construction, and drive the rapid development of prefabricated buildings in the coordinated development of the whole industry chain, which is becoming the key direction of the transformation of the construction industry.

The proportion of prefabricated buildings in the province increased by 83.85% year on year.

By traditional concrete pouring, such a building requires at least one year of construction period.” Zhu Lin told the reporter that the prefabricated buildings not only greatly improve the construction efficiency, but also become more green and environmentally friendly.

According to the Action Plan for Building Energy Conservation and Carbon Reduction in Anhui Province, newly established public buildings with a single aboveground area of more than 5000 square meters invested by the government or state-owned funds and new residential communities with a total area of more than 100000 square meters should be constructed by assembly.

The newly started area of prefabricated buildings in the province is 43.2527 million square meters, accounting for 35.63% of the newly started buildings.

The prefabricated construction mode is adopted.

As of September 2022, the province’s prefabricated buildings have accumulated 175 million square meters, and 101 projects have won provincial demonstration.