” The University of Tokyo is currently studying the future of architectural technology, and sekisuihouse has made a donation to start the project – to explore and study the “future of life”.

T-box will be used as a facility to cultivate creative talents, so that they can better Adapt to the future.

We very much welcome you to visit the exhibition facilities and use our ultimaker3d printer.

Next, we will ask Mr.

“As far as ABS materials are concerned, we are considering using various materials to print the joints of one-third of the building structure and actually use it.

Hirano believes that this will become a very critical facility for designers.

Mr.

3D printing technology has changed from a technology previously regarded as a novel or niche solution by some people to a more mature technology – from “rapid prototype manufacturing” to “additive manufacturing”.

Since then, we have regarded T-box as a ‘toolbox’ with various digital manufacturing equipment.

“T” refers to Tokyo, from theUniversity of Tokyo, technology and toolbox.

Of course, modeling has always been part of the architect’s work..

Hirano, director of sekisuihouse Kuma lab and assistant professor of the project, how students apply 3D printing in their daily college life, and what role ultimaker plays in it.

Hirano explained about the name of the project.

Recently, the “T-box” of sekisuihouse kumalab of the University of Tokyo chose ultimaker as the solution to meet the research needs of its architecture department.

The emergence of 3D printing has changed many industries, whether in manufacturing, construction, automobile and aerospace.

Hirano said.

Hirano said: “I believe that this factory will help students improve their technological level and explore other ways of growth, such as learning knowledge and technology related to manufacturing or digital manufacturing.

At that time, I went to the school of architecture of American University and saw that they were using ultimaker3d printers.

As a workshop with various digital manufacturing machines, it is mainly aimed at studying the relationship between digital technology and architecture.

“T-box means a lot of different things to us,” Mr.

But with the continuous development of digitalization, technology products such as ultimaker3d printers have become more and more important in many industries around the world.

When we asked him how he viewed the application of 3D printing in architecture in the past decade, Hirano admitted: “to be honest, I don’t use 3D printers in general unless I really need them.

It is mainly to help students prepare 3D modeling data needed for their design and printing of prototypes, and use it in meetings as design exercises.

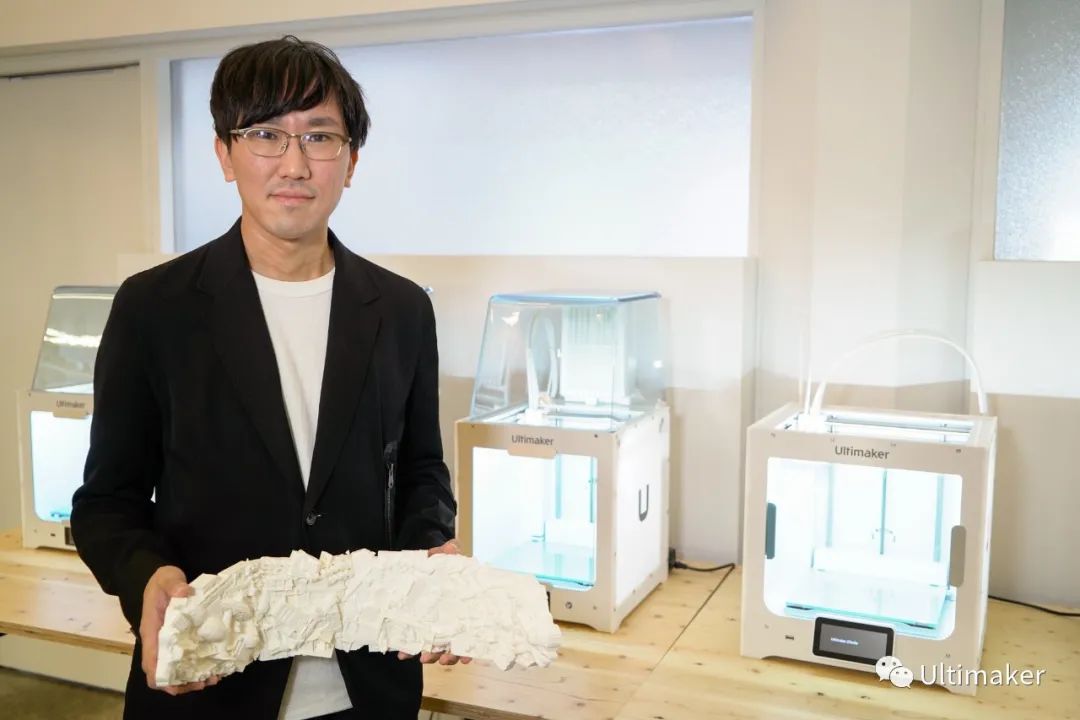

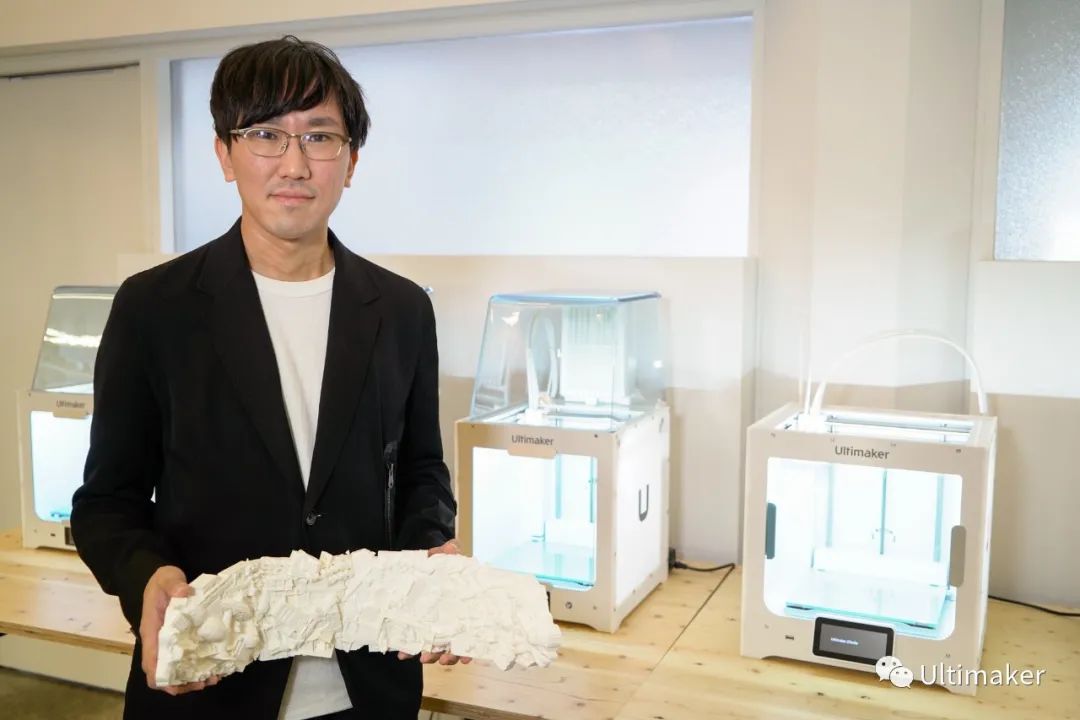

Hirano showed us one of his 3D printing building models.

Mr.

“T-box” will be put into use and operation in October 2021.

Most students praised the quality of ultimaker’s products.

” He added.

” Approaching T-box at present, T-box has 6 ultimaker3d printers.

Hirano commented: “with the increasing popularity of digital manufacturing, I have visited many similar facilities overseas.

Today, 3D printing technology has been widely used in university classrooms around the world, providing technical solutions for students and teachers to study innovative buildings, and creating a new standard for “future life”.

The main purpose of this cooperation is to combine these complementary advantages and capabilities to promote the development of future talents of “T-box”.

Hirano, now director of sekisuihouse kumalab and assistant professor of the project at the University of Tokyo, how all this started, “T-box project” was established by the architect Kengo Kuma in June, 2020.

Students have no choice but to buy 3D printers or make models by hand, which is the traditional method.

As for why they chose ultimaker, Mr.

However, Mr.

Considering that there have never been multiple 3D printers deployed in a laboratory on the campus, Mr.

Now with T-box, architecture students can easily create their carefully designed prototypes and use them for demonstration purposes.

In essence, we also want to challenge ourselves to find the most suitable materials according to different needs,” Mr.

There is no doubt that 3D printing has also become a part of the design cycle of architects and students.” Mr.

In fact, the right to use T-box does not only belong to students of Architecture Department.

In addition, when you need to make some advanced adjustments, you can still easily manipulate parameters to meet your needs Please.

At present, the T-box laboratory uses white PLA materials when the design is no longer restricted.

This concept of ‘just input data and start printing’ enables you to create works intuitively even without technical knowledge.

Their evaluation was that it was easy to use and easy to operate.” “Ultimaker is a good choice because it can handle a variety of consumables and has high-quality printing accuracy, speed and responsiveness.

Hirano and his students have begun to conduct in-depth research on various possibilities brought about by the compatible application of ultimaker and third-party consumables.

In the past, the Department of architecture did not have production facilities equipped with digital manufacturing tools.

New Zealand builders please note

New Zealand builders please note  Neo Tech · Monitoring Service · Solving Pain Points: burglaries happen frequently, stores are smashed and robbed, economic losses are heavy, and there is

Neo Tech · Monitoring Service · Solving Pain Points: burglaries happen frequently, stores are smashed and robbed, economic losses are heavy, and there is