(1) The factory lightning protection is divided into overall structure lightning protection, that is, the lightning protection of the main power house.

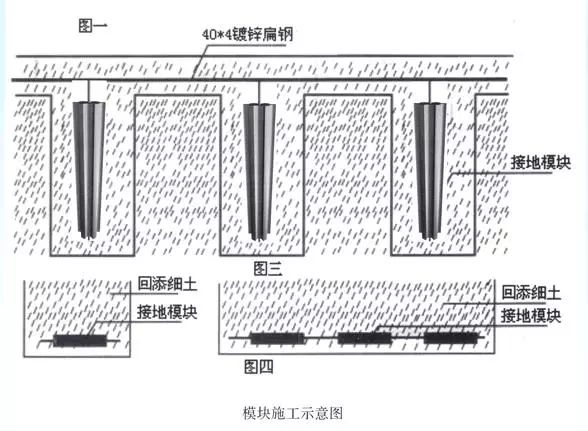

If the conditions are not good, electrolytes shall be added and / or soil shall be replaced.

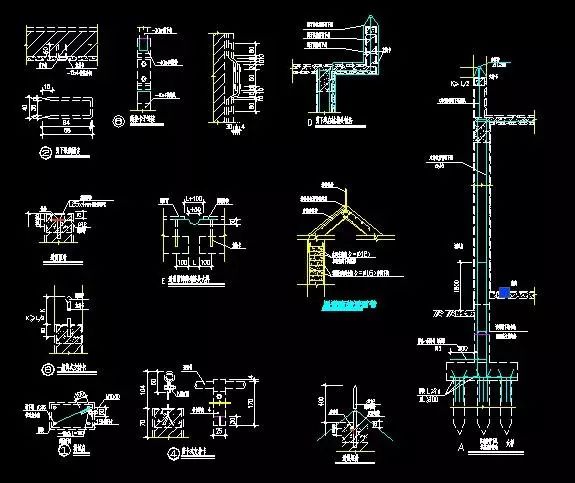

The blue line with fork indicates the lightning strip (lightning strip) and support.

If the requirements are not met, the grounding electrode shall be added.

The cement concrete roof shall be connected with lightning strip or lightning rod, the ground outside the wall shall also be reserved with grounding test points, and the steel structure shall be directly led to the roof with galvanized flat iron.

The legend uses hot-dip galvanized round steel Ф 12 as lightning strip, when laid horizontally, the spacing between supports is 1.0m and that at corners is 0.5m.

Usually, the lightning rod and lightning wire on the roof are welded with the main reinforcement of the building, and then connected with the grounding body on the ground to form the lightning protection device of the building, that is, the combination of natural grounding body and artificial grounding body to achieve the best lightning protection effect.

The grounding system must be repeatedly grounded.

The lightning strip not in the same plane shall be vertically connected, and the down lead shall be provided with a disconnection card 1.8m away from the ground, with a total of two for telemetry.

② See the attached grounding plan for the Foundation Grounding plan.

A MEB is set in the low-voltage distribution room on the first basement floor to prevent irrelevant personnel from touching.

The lightning strip is welded and overlapped, and the round steel is welded on both sides.

The grounding sub collection rows of each floor are set in the cable well, and 40 wires are used between the collection rows of each floor × 4 hot dip galvanized flat steel connection.

(1) Lightning protection and grounding plan the lightning protection and grounding plan of a building usually shows the composition and installation requirements of the lightning protection and grounding system of the building, which is generally composed of roof lightning protection plan, Foundation Grounding plan, etc.

The total resistance of the building shall not be greater than 1 ohm.

The hot-dip galvanized round steel is welded and connected with the lightning strip nearby; The lightning strip is welded with the downlead of the main reinforcement at each connection point, and each column reinforcement is welded with each main reinforcement at the depth.

The metal components of the building exterior wall shall be connected with the building lightning arrester and down lead as an equipotential body.

This is relatively simple for lightning protection construction, but it is difficult to describe, which is generally these! 4、 Reading skills of lightning protection and grounding plan lightning protection and grounding is the protective measures taken for buildings, electrical equipment and facilities in order to shed lightning current.

Source: in case of infringement, please contact to delete.

The white line indicates the lightning protection grid.

The lightning protection and grounding series of buildings are generally divided into lightning rod and lightning wire.

7) Grounding resistance: the sum of the grounding resistance of the grounding body or natural grounding body becomes the grounding resistance of the grounding device, and its value is equal to the ratio of the grounding voltage of the grounding device to the current flowing into the ground through the grounding body.

The working mode, such as the separation of ground wire and zero wire, can also be combined into one and led to the power system (or equipment).

The working grounding and protective grounding are led out independently in the distribution room, and the system can be combined into one.

It is made of hot-dip galvanized round steel with a diameter of not less than 10mm.

Then it is connected with the main body of the reinforcement or steel structure of the main power house.

(3) Instrument grounding system.

Protective grounding is the shell grounding of live equipment.

The horizontal grounding sub collector to the grounding sub collector is connected with vv-1x35mm2, and the horizontal sub collector to the metal pipe and equipment metal shell is connected with bv-1x25mm2.

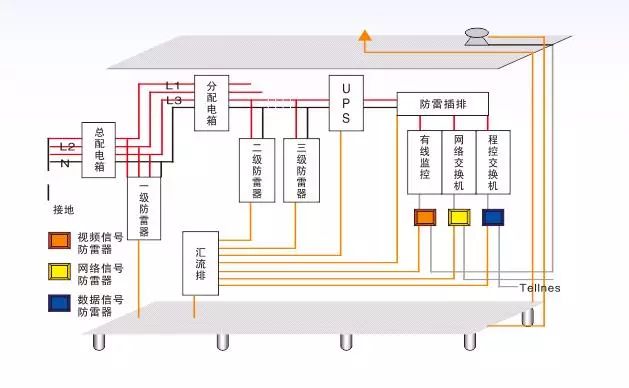

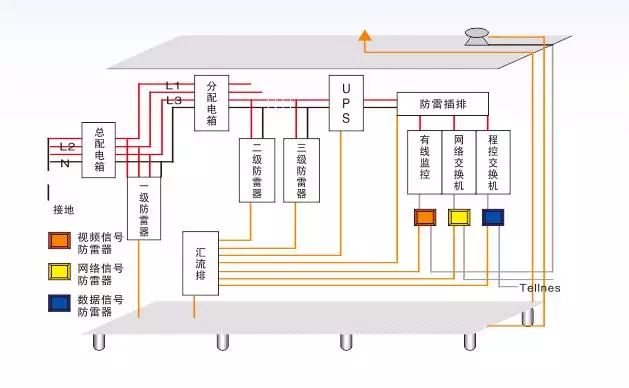

AC power lightning protection module is applicable to the power protection of distribution room, distribution cabinet, switch cabinet, AC and DC distribution panel, communication, electronics, power, network, energy, railway, highway and other systems· There are outdoor input distribution box and building floor distribution box in the building· For low voltage (220 / 380VAC) industrial power grid and civil power grid· Signal lightning arrester is used for overvoltage protection of line intrusion; Lightning rod is used for direct lightning protection; In the power system, it is mainly used for three-phase power input or output terminals in the power supply panel of the automation machine room and the main control room of the substation.

The lightning strip construction is as close as possible to the outside of the outer wall of the house.

① See the attached lightning protection plan for the roof lightning protection plan.

(4) For anti-static grounding, such as oil pipe, there must be a reliable grounding (system or independent) every 35 meters (elbow), with a resistance of less than 30 Ω.

First, lightning protection and grounding are divided into two concepts.

The downlead of lightning protection device shall use the main reinforcement outside the building structure (no less than two).

Zero and earth can no longer be one.

The upper and lower connection points of the reinforcement shall be lap welded, and its upper end shall be connected with the roof lightning protection device, its lower end shall be connected with the ground grid, and its middle shall be welded with each voltage equalizing belt.

2) Down lead: conductor used to conduct lightning current from lightning arrester to grounding device.

At the same time, the grounding resistance is also a sign of the level of the constant grounding device.

4) Grounding body (pole): the metal conductor buried in the soil and in direct contact with the earth is called grounding body.

Joint grounding is a grounding method that shares a group of grounding bodies for equipment working grounding, protective grounding and building lightning protection grounding.

(2) The grounding of power supply system is divided into protective grounding and working point grounding.

The grounding of power system is generally installed and used separately from the lightning protection grounding system to avoid the damage of lightning to electrical equipment.

There are also separate ways, TN-S system.

When welding the lightning strip, the reinforcement shall be straightened in advance.

The support shall be installed on a straight line with the same height.

The lightning strip in the figure shall be laid according to the location where the building is easy to be struck by lightning.

3) Grounding wire: a metal conductor that does not carry current under normal conditions for the connection between the grounding terminal of electrical equipment and tower and grounding body or zero line.

First, lightning protection to prevent damage caused by lightning; Second, electrostatic grounding to prevent electrostatic hazards.

The project adopts combined grounding, as shown in Figure 8.20.

5) Grounding device: the general name of grounding wire and grounding body.

3、 For the drawing reading method, first look at the description, then look at the marked installation position of the line in the drawing, and then look at whether there is a downlead at each column or shear wall.

The grounding resistance of the system is less than 1 Ω and cannot be connected with lightning protection grounding.

When laying vertically, the support spacing is 1.5m and the support is 12mm × 4mm Flat steel, l = 150mm.

Working point grounding refers to zero line grounding.

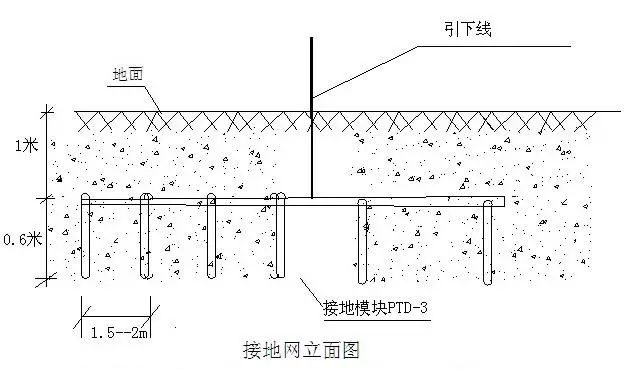

The grounding electrode shall be L50 every 5m × fifty × 2500 hot-dip galvanized angle steel, buried depth 0.8m..

At the expansion joint of the building, soft braided copper wire can be used for bridging, or round steel can be used to bend and reserve expansion.

The building is considered as class II lightning protection building, and the grounding body uses two main reinforcements in the concrete of the building foundation and the grid size around the building is not greater than 10m × The 10m laid annular grounding body shall be welded together, and the grid intersection and the reinforcement shall be firmly welded.

2、 Some concepts of lightning protection and grounding device 1) lightning receiving device: metal rod (lightning arrester) that directly or indirectly receives lightning, such as lightning rod, lightning strip (Network), overhead ground wire and lightning arrester.

It is very necessary for the safe use of buildings, electrical equipment and facilities.

Generally, the support spacing is 1m, the corner is 0.5m, and the height is not less than 15cm.

6) Grounding grid: a network grounding device composed of vertical and horizontal grounding bodies with the functions of current relief and voltage equalization.

The main foundation is laid with grounding electrode and grounding strip to form a grounding grid, and the grounding resistance is less than 10 Ω.

According to the lightning protection classification of buildings, the size of the grid is different, but it is required to be connected with the lightning protection belt.

The method of grounding grid is the same as that of lightning protection grounding, and the grounding resistance is less than 4 Ω.

It is divided into vertical grounding body and horizontal grounding body.

The metal components of the roof pass through Ф 10.

For high-rise buildings, in addition to roof lightning protection, there are lightning strip and grounding device to prevent side lightning.

It is composed of grounding body, grounding lead-in line, grounding collector and grounding electrode.

The welding length is 6 times the diameter of the round steel.